* In order to offer the best variety of sizes, all conveyor rollers are custom built and therefore subject to a delay of 7-10 standard business days. Because all conveyor rollers are custom built, once the payment has been processed it is impossible to cancel or refund an order.

Frequently Asked Questions

Conveyor rollers are integral components of conveyor systems, designed to move products, materials, or packages from one point to another with minimal effort. Here's how they work:

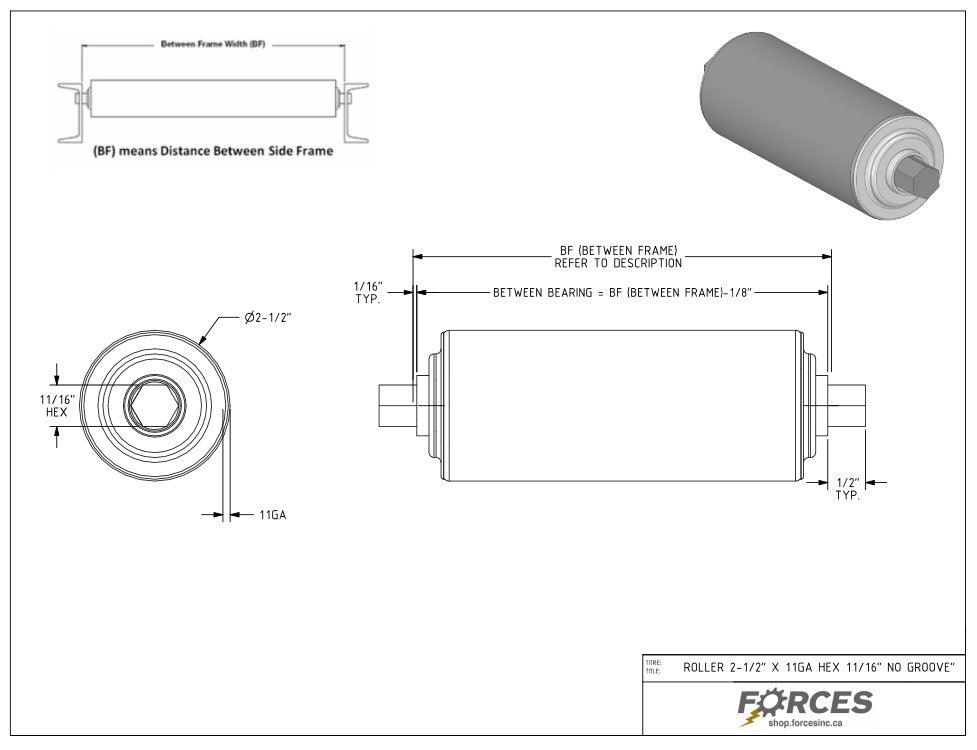

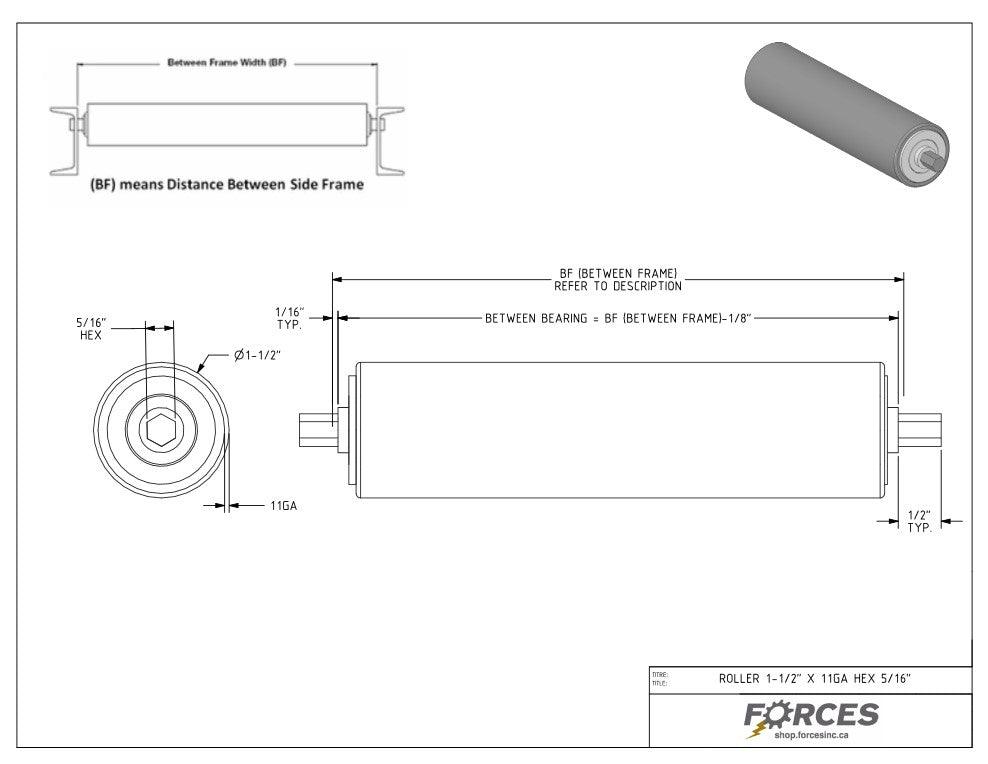

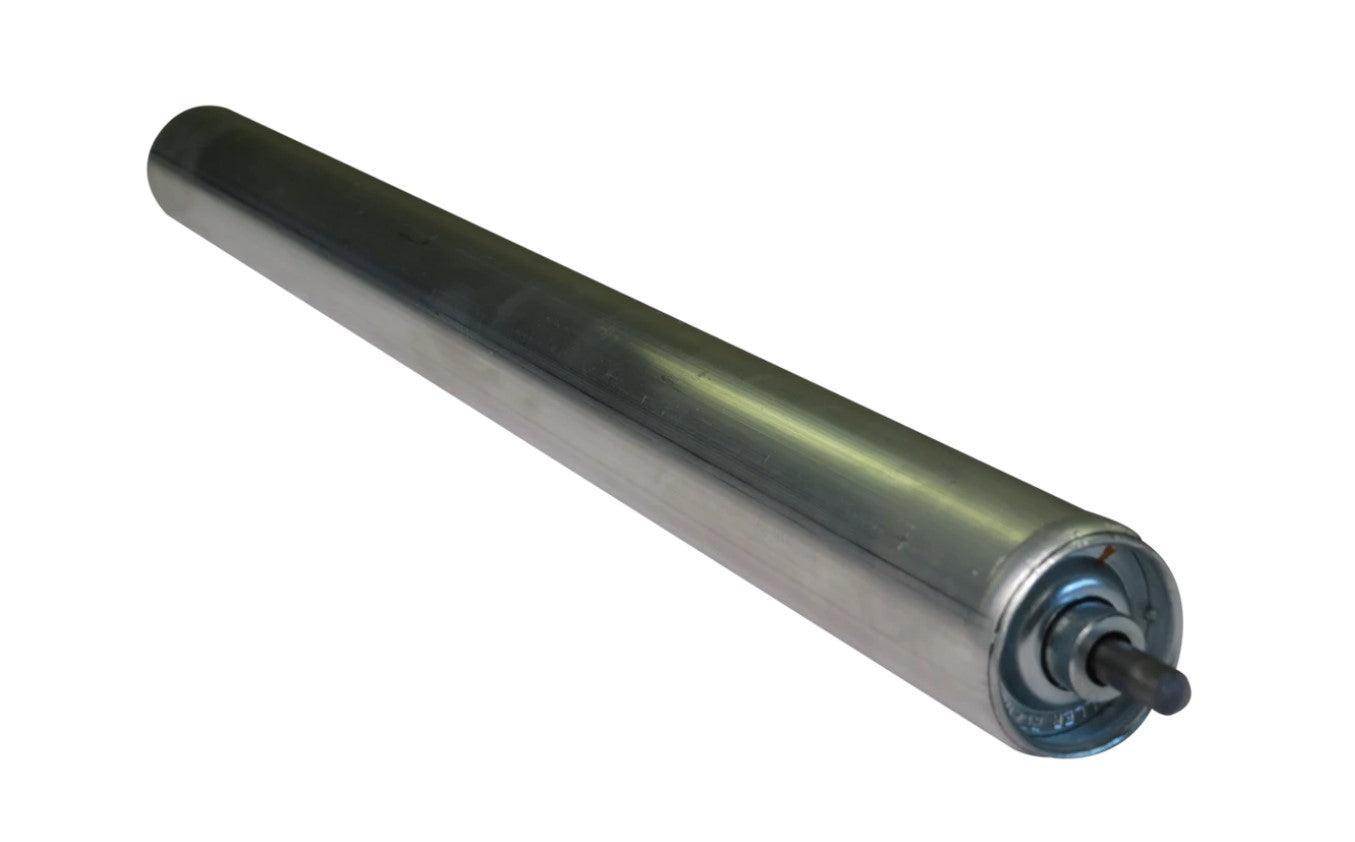

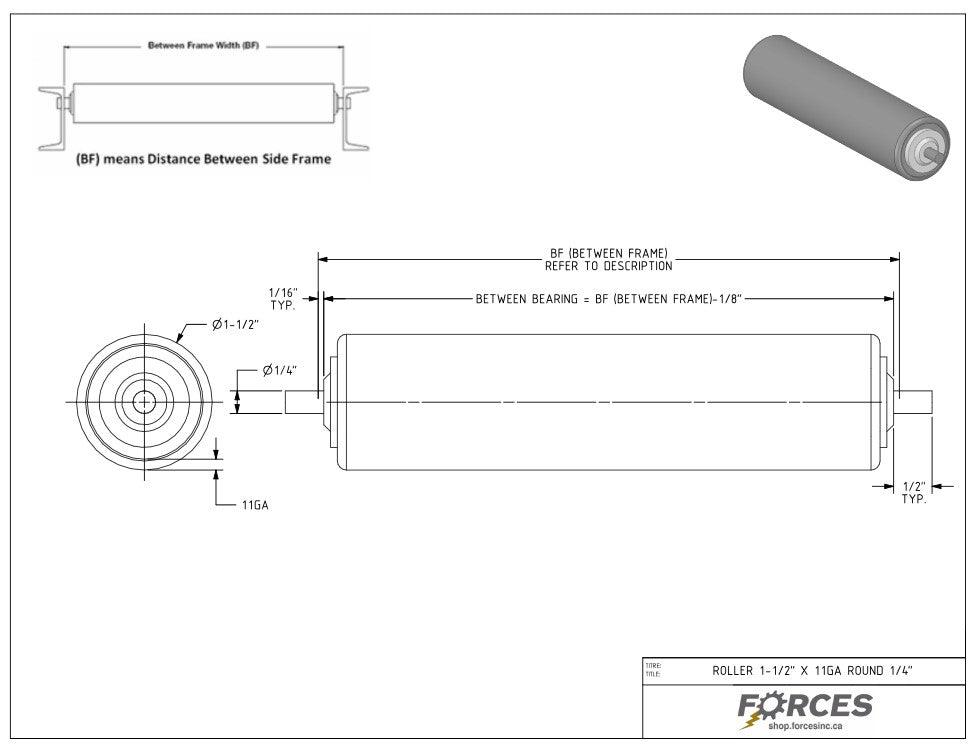

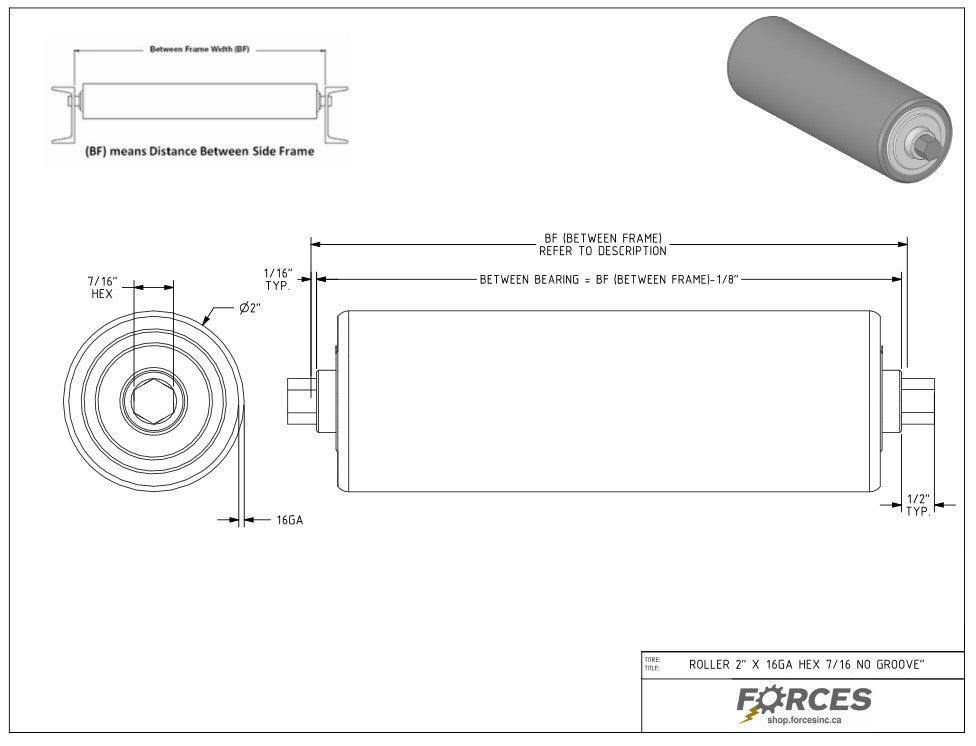

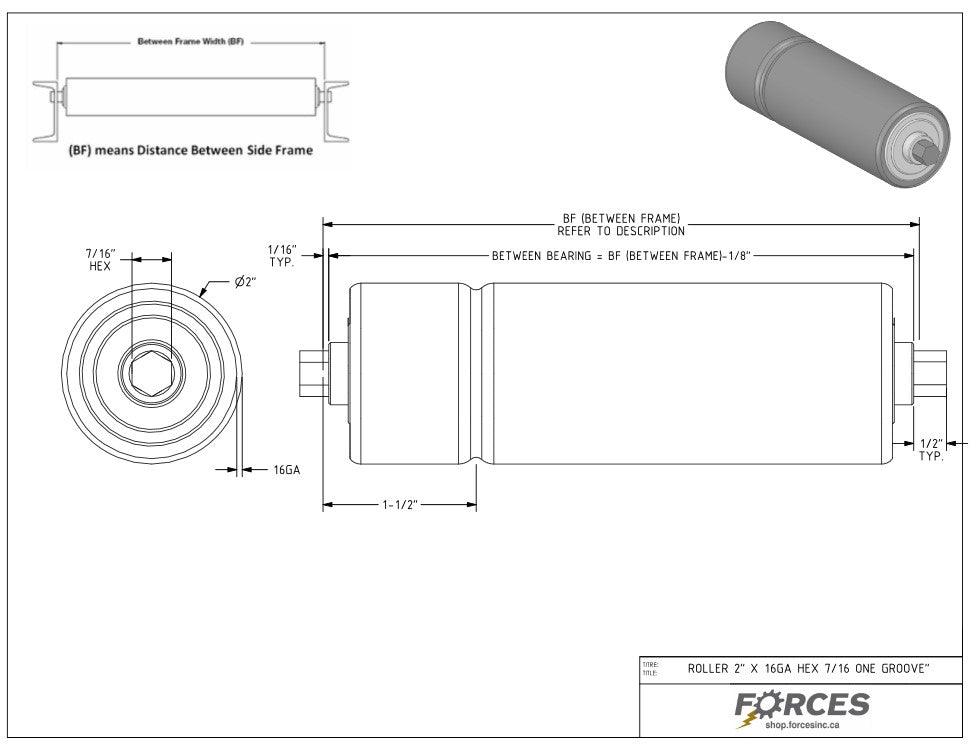

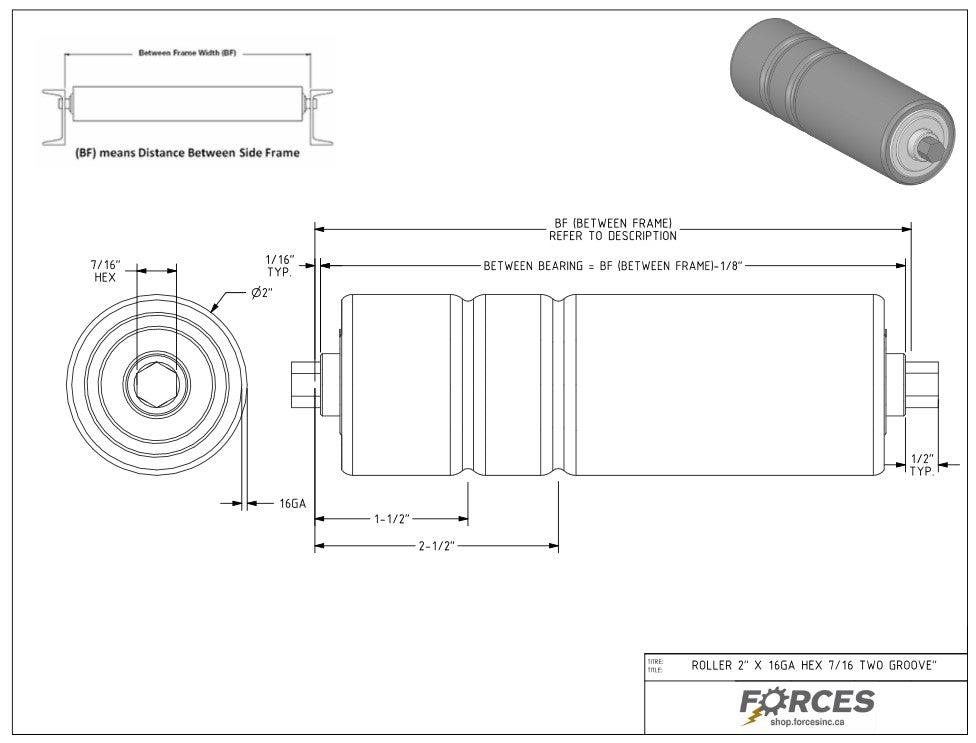

- Roller Mechanism: Conveyor rollers are cylindrical components that rotate around their central axis. They are typically mounted on a frame and spaced evenly to support and move materials.

- Power Source: Rollers can be powered by various means, including manual pushing, gravity, or motor-driven mechanisms. In powered systems, motors drive the rollers to maintain continuous movement.

- Material Transport: As the rollers rotate, they facilitate the smooth and consistent movement of items placed on them. The spacing and alignment of the rollers ensure stability and prevent items from falling off.

- Friction Reduction: The design of the rollers minimizes friction, allowing for efficient and effortless transportation of goods across the conveyor system.

Conveyor rollers are essential for streamlining material handling processes, improving efficiency, and reducing manual labor in various industries.

Conveyor rollers are used in a wide range of applications due to their versatility and efficiency. Common uses include:

- Material Handling: Conveyor rollers are used to transport raw materials, components, and finished products in manufacturing plants and warehouses.

- Logistics and Distribution: They facilitate the movement of packages, parcels, and goods in distribution centers and shipping facilities.

- Automated Systems: Conveyor rollers are integral to automated assembly lines, ensuring the smooth flow of products through different stages of production.

- Food and Beverage Industry: They are used to transport food products and packaging materials in processing plants and packaging lines.

- Retail and E-commerce: Conveyor rollers assist in order fulfillment processes by moving products through sorting and packing areas.

Their ability to handle a variety of materials and loads makes conveyor rollers indispensable in numerous industries.

Proper maintenance of conveyor rollers is crucial to ensure their longevity and optimal performance. Here are some maintenance tips:

- Regular Inspections: Conduct routine inspections to check for signs of wear, damage, or misalignment. Address any issues promptly to prevent further damage.

- Cleaning: Keep the rollers and conveyor system clean to prevent the buildup of dirt, debris, and contaminants that can affect performance.

- Lubrication: Apply appropriate lubrication to the roller bearings and moving parts to reduce friction and prevent wear.

- Alignment: Ensure that the rollers are properly aligned and spaced to maintain smooth and consistent movement of materials.

- Replacement: Replace worn or damaged rollers promptly to avoid disruptions in the conveyor system and maintain efficient operation.

Adhering to these maintenance practices will help extend the lifespan of your conveyor rollers and ensure reliable performance.