Advantages of Sanitary Gaskets

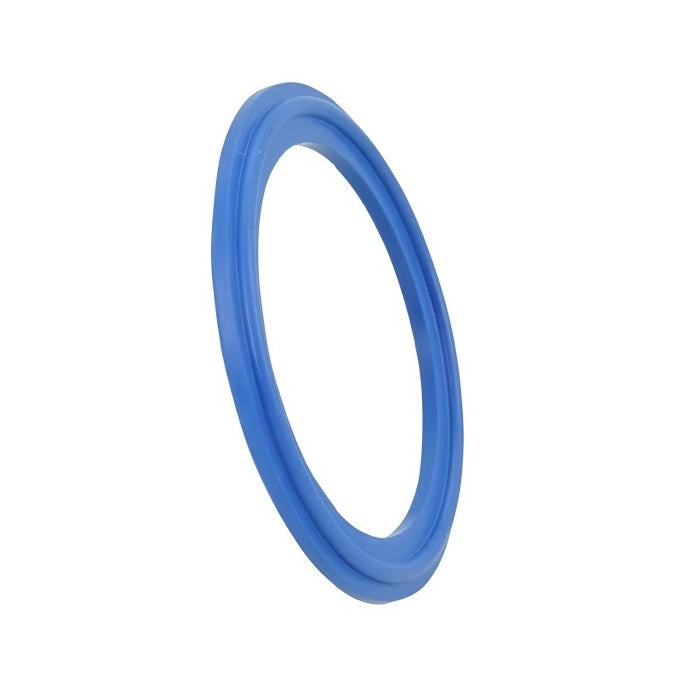

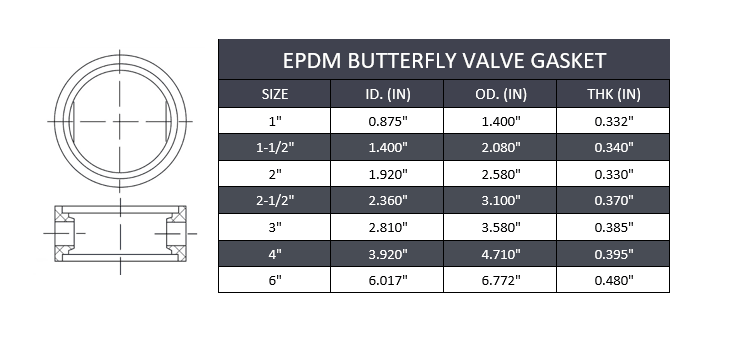

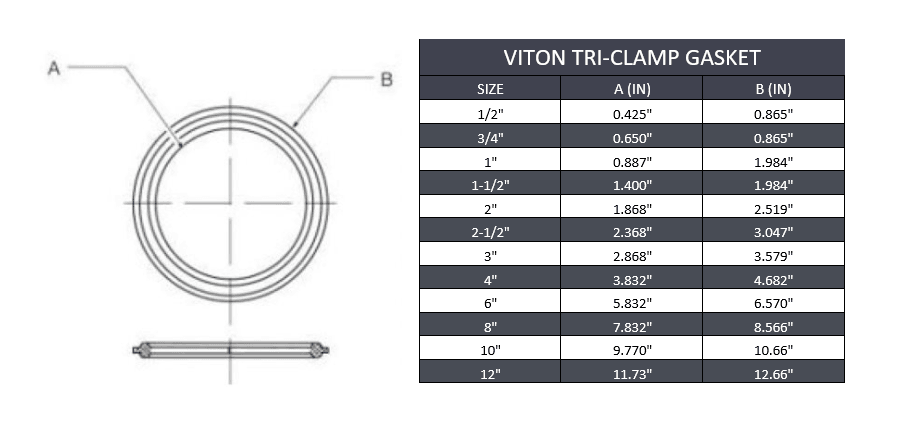

• High Purity Materials: Made from materials like EPDM, Silicone, Viton, and PTFE, which are safe for use in food, beverage, and pharmaceutical applications.

• Compliance with Standards: Many sanitary gaskets meet industry standards, including USP Class VI and FDA compliance, ensuring they are safe for use in sensitive environments.

• Temperature and Chemical Resistance: Designed to withstand high temperatures, steam, and chemical exposure, making them suitable for harsh processing environments.

• Smooth, Non-Porous Surface: Prevents the buildup of bacteria and contaminants, ensuring that fluids remain pure and uncontaminated.

Applications of Sanitary Gaskets

• Food and Beverage Processing: Essential in providing secure seals in piping systems, tanks, and processing equipment to prevent contamination.

• Pharmaceuticals: Ensure that drugs and other products are processed in a clean environment, free from contaminants.

• Biotechnology: Used in applications where the purity of fluids and biological materials is critical, ensuring sterile conditions.

• Dairy Production: Seal connections in pasteurizers, homogenizers, and other equipment, maintaining product safety and quality.