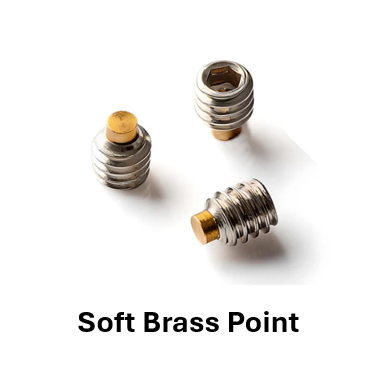

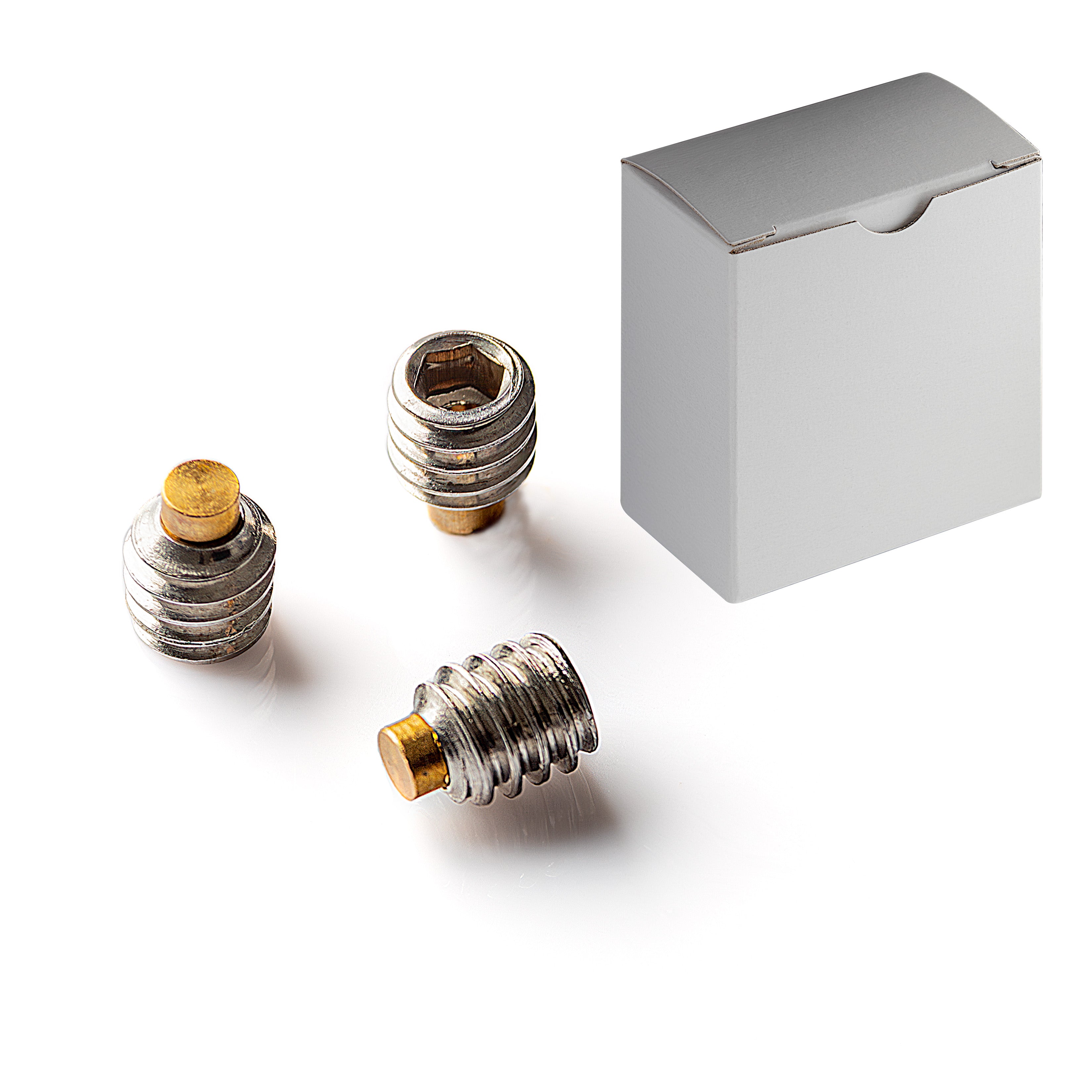

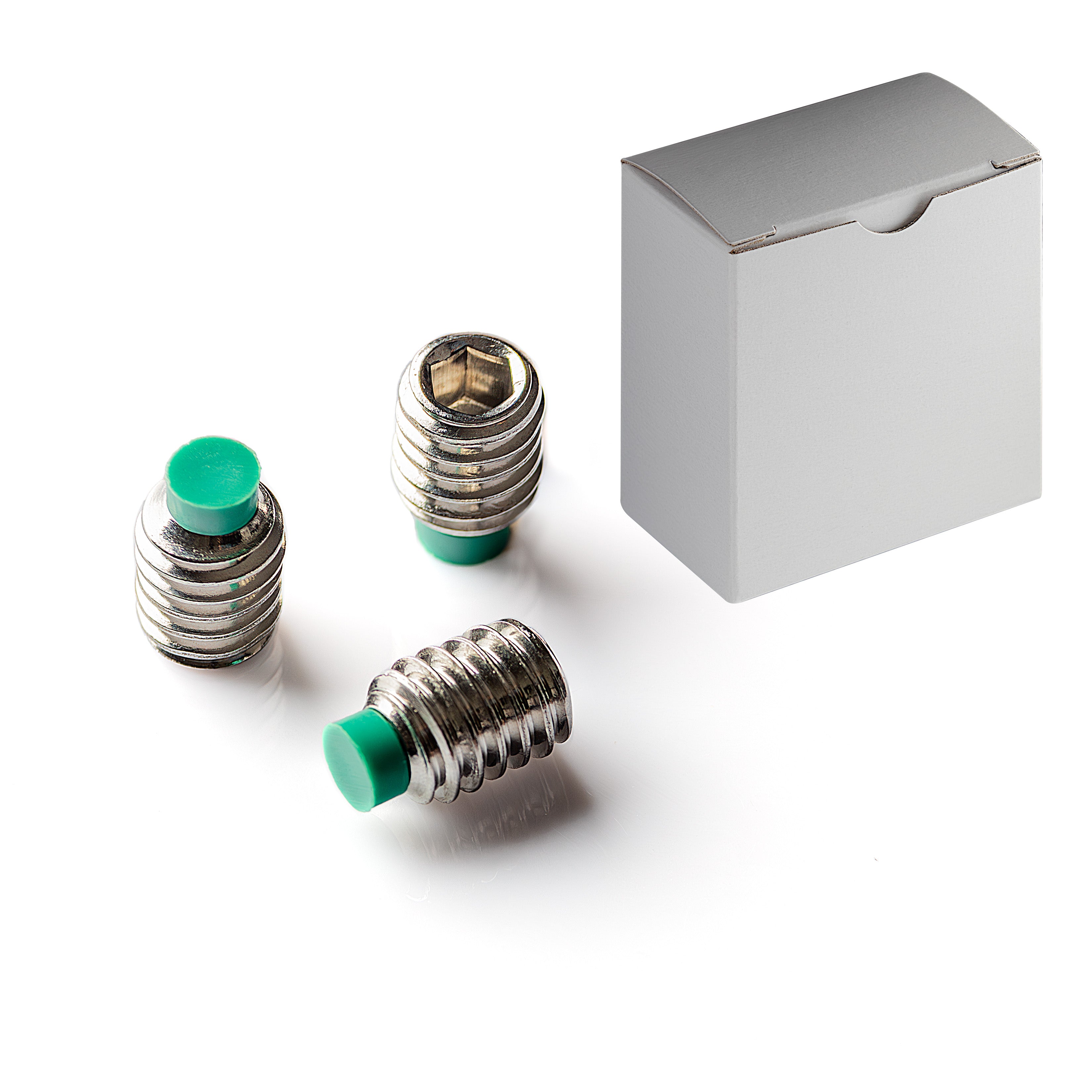

Socket set screws, also known as grub screws, are headless screws with a hexagonal drive socket. They are used to secure an object within or against another object without protruding from the surface. These screws are essential for creating secure and discreet connections in various applications, ensuring the stability and safety of mechanical assemblies.