Sanitary Valves

Sanitary valves are designed to meet the stringent hygiene standards required in industries like food, beverage, and pharmaceuticals. They ensure the safe and efficient control of fluids, preventing contamination and maintaining product integrity.

Types of Sanitary Valves

• Butterfly Valves: Known for their compact design and ease of use, ideal for quick shut-off applications.

• Ball Valves: Provide tight sealing and are suitable for high-pressure applications.

• Diaphragm Valves: Excellent for controlling flow in sterile environments, often used in pharmaceutical processes.

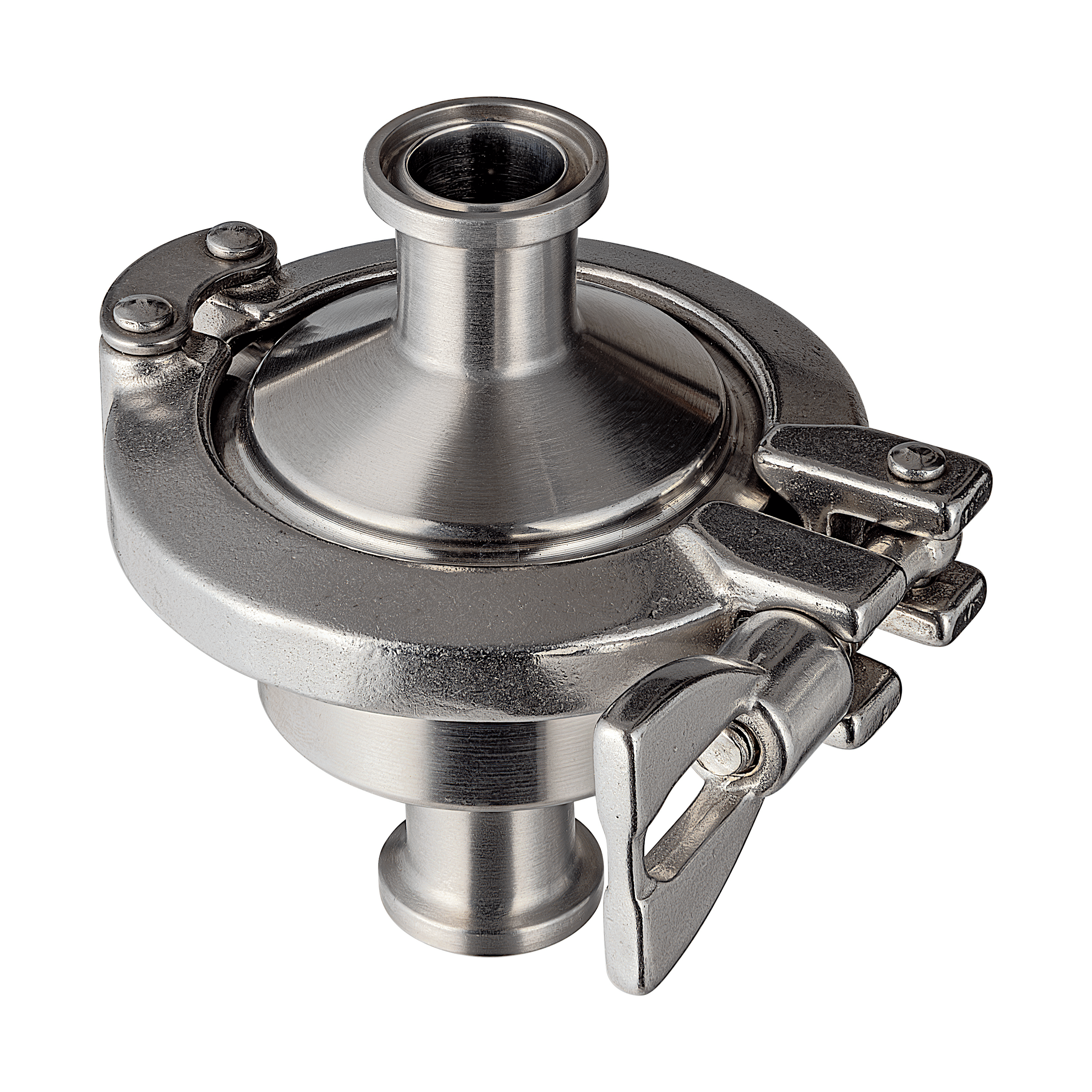

• Check Valves: Prevent backflow, ensuring that the process fluid flows in the correct direction.

Advantages of Sanitary Valves

• Hygienic Design: Made from materials like stainless steel, which are easy to clean and sterilize.

• Durability: Resistant to corrosion and wear, ensuring long-term reliability.

• Compliance: Meet industry standards such as FDA, 3-A, and EHEDG, ensuring safety and quality.

Applications of Sanitary Valves

• Food and Beverage Industry: Used in processes like brewing, dairy production, and bottling to maintain hygiene and product quality.

• Pharmaceutical Industry: Essential in the production of medicines and vaccines, where contamination control is critical.

• Biotechnology: Used in the production of biological products, ensuring sterile conditions are maintained.