Filters (0)

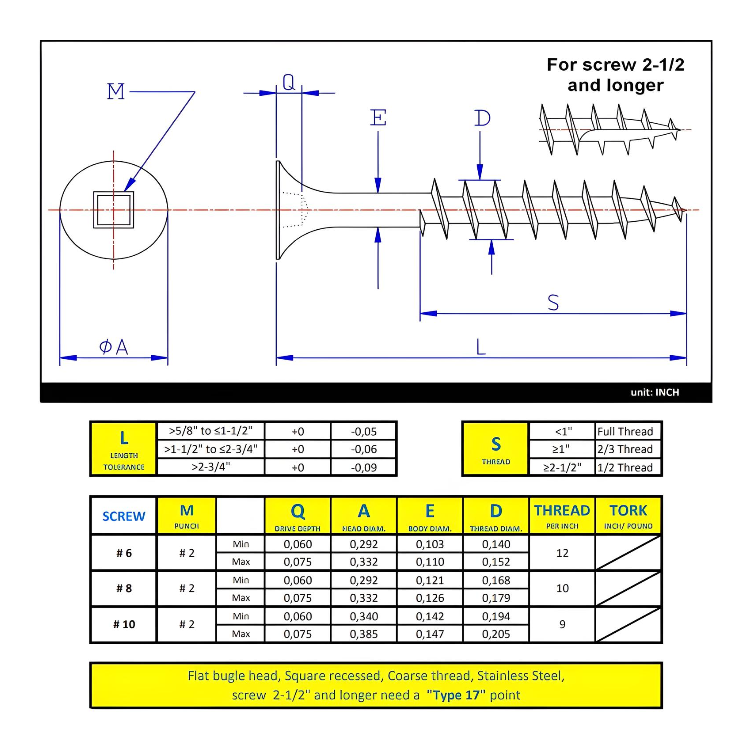

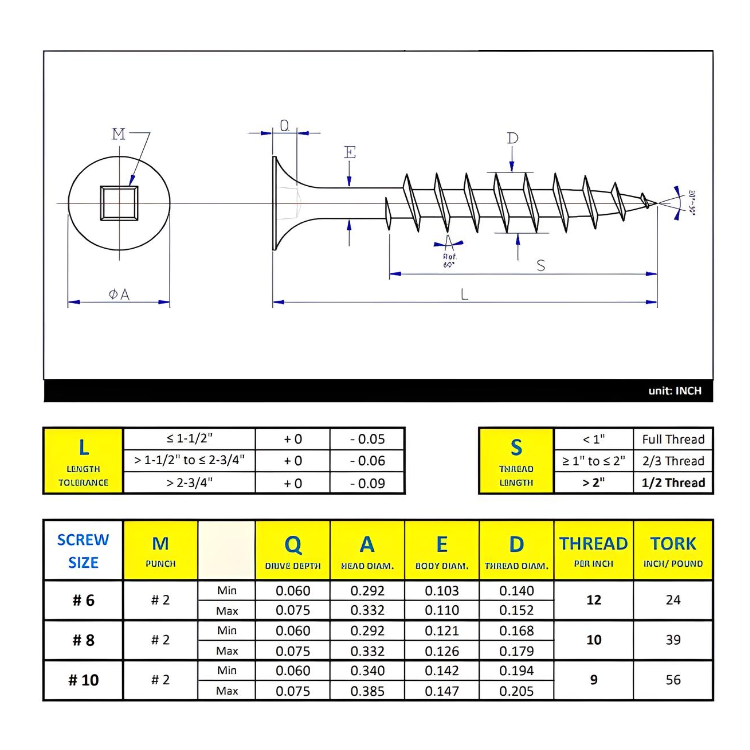

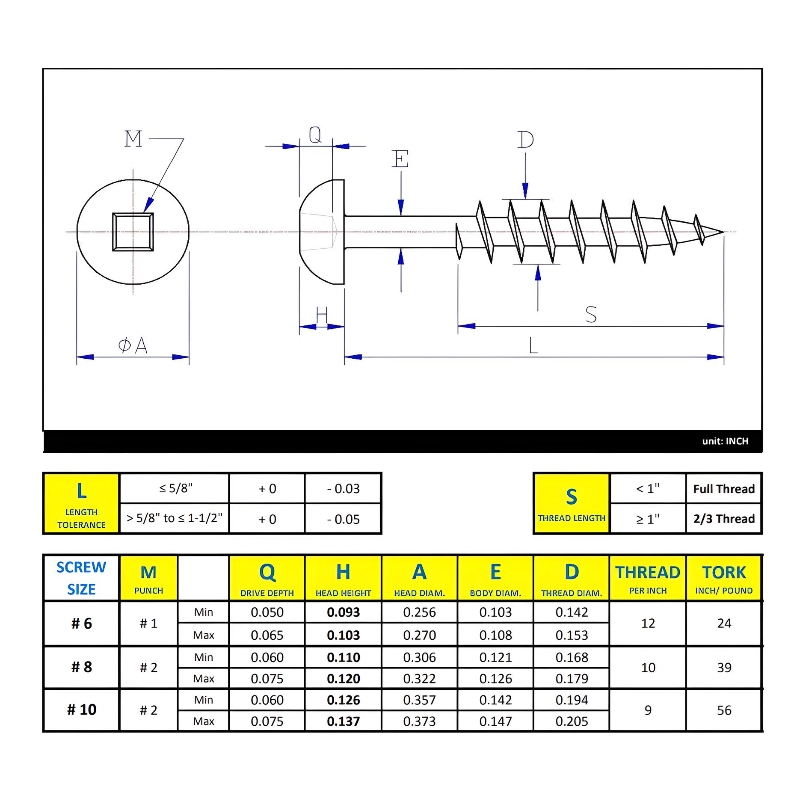

Deck Screws are designed to provide strong, durable fastening for wood and composite decking applications. Constructed from corrosion-resistant materials, they resist rust and wear in outdoor environments. Precision-threaded design ensures easy installation, secure holding power, and reduced splitting of the material. Ideal for residential and commercial decking projects, these screws deliver reliable performance and long-lasting structural integrity.