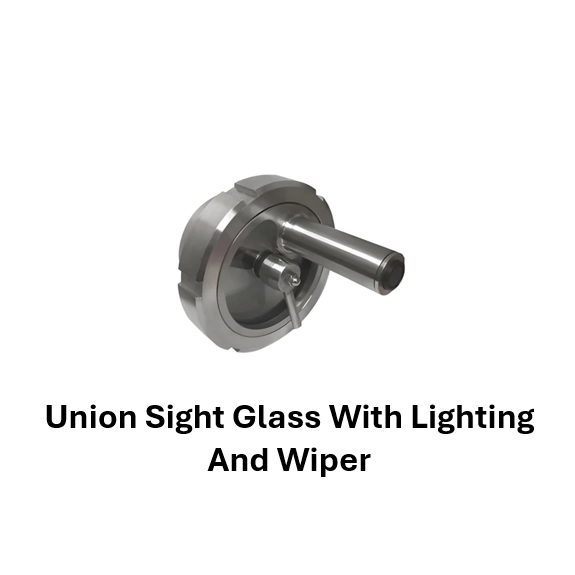

Monitor flow and clarity in your sanitary process lines with our high-quality Sight Glasses. Designed for visual inspection of fluids in food, beverage, dairy, and pharmaceutical systems, these components offer critical insight without interrupting production. Constructed with durable stainless steel and high-impact, heat-resistant glass, they provide clear visibility and reliable performance under pressure. Available in threaded, clamp, and weld ends, our sight glasses support both horizontal and vertical installations for maximum versatility.

100% Money back guarantee

30 days money-back.

Any questions or need help ?

Contact us by chat, mail or by phone.

100% Secure payments

Secure payment methods.