Sanitary Fittings

Our sanitary fitting products are designed to meet the stringent hygiene and safety standards required in industries such as food and beverage, pharmaceuticals, and biotechnology. Whether you need fittings for processing, transportation, or storage, our products ensure cleanliness, reliability, and efficiency in your operations.

You can choose from a wide range of products, such as tri-clamp fittings, ISO-K & KF fittings, butt-weld fittings, and more.

For any information about products, please contact us at orders@forcesinc.ca

Frequently Asked Questions

Sanitary fittings are specialized components used to connect and control the flow of liquids in systems where hygiene is a critical concern. These fittings are designed to be easily cleaned and to prevent contamination, making them ideal for use in industries where maintaining sanitary conditions is essential. Common materials used in sanitary fittings include stainless steel and other corrosion-resistant alloys.

Sanitary fittings are used in a variety of applications across several industries, including:

- Food and Beverage: Used in processing and packaging systems to ensure hygiene and prevent contamination of food products.

- Pharmaceuticals: Essential for manufacturing and processing pharmaceuticals, ensuring that products are free from contaminants.

- Biotechnology: Used in bioprocessing systems to maintain sterile conditions during the production of biologics and other biotech products.

- Dairy Industry: Employed in the processing of milk and dairy products to maintain cleanliness and product safety.

- Brewing: Used in breweries for the hygienic transfer and processing of beer and other beverages.

Their ability to maintain high levels of cleanliness and prevent contamination makes sanitary fittings indispensable in these industries.

Sanitary fittings work by providing a secure and hygienic connection between pipes and other components in a fluid processing system. Here's how they function:

- Connection: Sanitary fittings connect different sections of piping and equipment using clamps, welds, or threads, ensuring a secure fit.

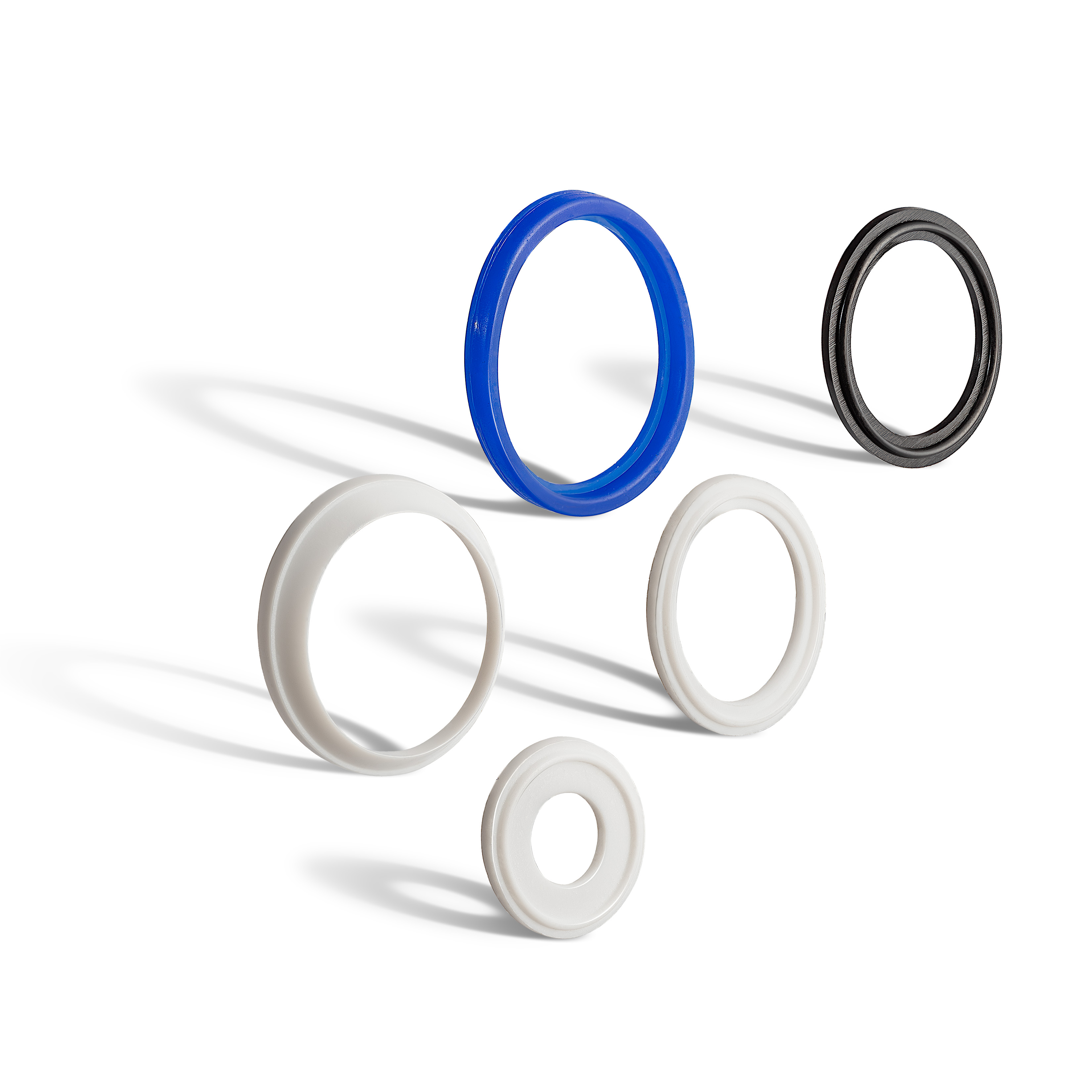

- Sealing: They often use gaskets or O-rings made from materials that are resistant to chemicals and high temperatures to create a tight seal, preventing leaks and contamination.

- Flow Control: Some sanitary fittings include valves and other mechanisms to control the flow of liquids, ensuring precise operation and hygiene.

- Easy Cleaning: Designed for easy disassembly and cleaning, sanitary fittings allow for thorough cleaning and sterilization, essential in maintaining sanitary conditions.

This combination of secure connections, effective sealing, and easy cleaning ensures that sanitary fittings maintain the highest hygiene standards in fluid processing systems.

Sanitary fittings are manufactured using stringent processes to ensure they meet the highest standards of hygiene and durability. The typical manufacturing process involves:

- Material Selection: High-quality stainless steel or other corrosion-resistant materials are chosen for their durability and ability to withstand cleaning and sterilization processes.

- Precision Machining: The materials are precisely machined to create the various components of the fittings, ensuring accurate dimensions and smooth surfaces.

- Welding and Assembly: Components are welded or assembled using techniques that ensure smooth, crevice-free joints to prevent bacterial growth and contamination.

- Surface Finishing: The fittings are polished to a high finish to make cleaning easier and to further prevent contamination.

- Quality Control: Each fitting undergoes rigorous testing and inspection to ensure it meets industry standards for hygiene, strength, and performance.

This careful manufacturing process ensures that our sanitary fittings provide optimal performance and reliability in demanding hygienic applications.