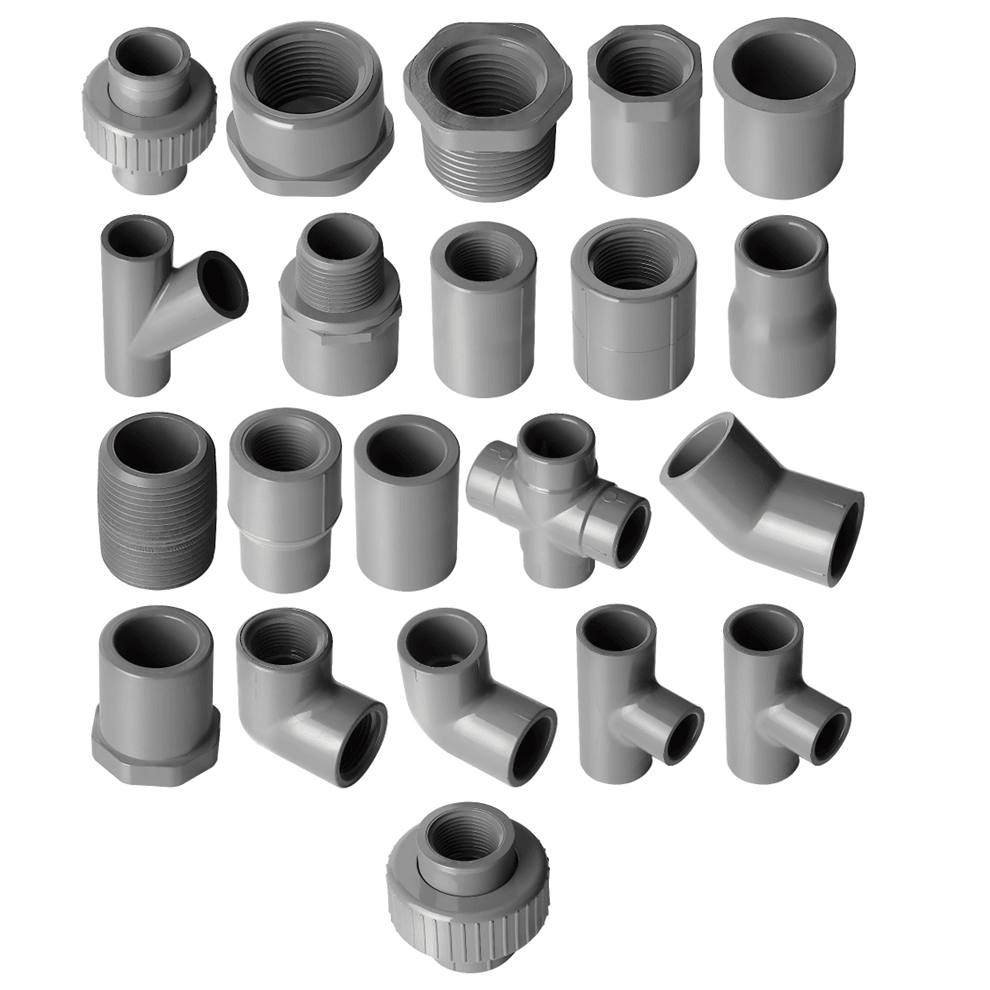

PVC Fittings

Our extensive selection of PVC fittings is designed to meet the diverse needs of various plumbing, irrigation, and industrial applications. Our fittings are renowned for their durability, corrosion resistance, and ease of installation, making them an ideal choice for both residential and commercial projects.

Whether you need fittings for water supply, drainage systems, or irrigation setups, our products are engineered to deliver superior results. Explore our comprehensive collection to find the perfect PVC fittings for your specific needs.

PVC Fittings FAQ

PVC fittings are components used to connect sections of PVC pipe together or to change the direction of the piping system. They are made from polyvinyl chloride (PVC), a durable and versatile plastic material that is widely used in plumbing, irrigation, and industrial applications. PVC fittings include various types such as elbows, tees, couplings, and adapters, each designed for specific functions within a piping system.

PVC fittings are used in a wide range of applications due to their versatility and durability. Common uses include:

- Plumbing: PVC fittings are used to connect pipes in residential and commercial plumbing systems, including water supply lines, drainage systems, and sewage systems.

- Irrigation: In agricultural and landscaping applications, PVC fittings are used to construct efficient irrigation systems that ensure proper water distribution.

- Industrial Applications: PVC fittings are used in various industrial processes, including chemical processing, wastewater treatment, and ventilation systems.

- HVAC Systems: They are used in heating, ventilation, and air conditioning systems to ensure proper air flow and distribution.

Their ability to provide secure and leak-proof connections makes PVC fittings essential in many piping systems.

PVC fittings work by creating secure and watertight connections between sections of PVC pipe. Here’s how they function:

- Connection: The ends of the PVC pipes are inserted into the sockets or threaded ends of the fittings.

- Sealing: For solvent-welded fittings, a special PVC solvent cement is applied to the pipe and fitting surfaces, which chemically bonds them together, creating a strong and leak-proof seal. For threaded fittings, Teflon tape or thread sealant is used to ensure a tight connection.

- Support: The fittings provide structural support and direction changes to the piping system, ensuring proper flow and distribution of fluids or gases.

This simple yet effective mechanism ensures reliable connections in various piping applications.

PVC fittings are manufactured using high-quality PVC resin and advanced production processes to ensure durability and precision. The typical manufacturing process involves:

- Material Preparation: High-quality PVC resin is mixed with stabilizers, plasticizers, and other additives to achieve the desired properties.

- Molding: The prepared PVC compound is then injected into molds to form the desired shapes of the fittings using techniques such as injection molding or extrusion.

- Cooling and Ejection: The molded fittings are cooled to solidify and then ejected from the molds.

- Finishing: The fittings are trimmed and finished to remove any excess material and ensure smooth surfaces and precise dimensions.

- Quality Control: Each fitting undergoes rigorous testing and inspection to ensure it meets industry standards for strength, durability, and performance.

This meticulous manufacturing process ensures that our PVC fittings provide reliable and long-lasting performance in various applications.