Stainless Steel Pipe Flanges

Stainless steel pipe flanges are critical components in various industries, known for their excellent corrosion resistance, durability, and ability to withstand high temperatures and pressures. These flanges are essential for creating secure and leak-proof connections in piping systems.

Types of Stainless Steel Pipe Flanges

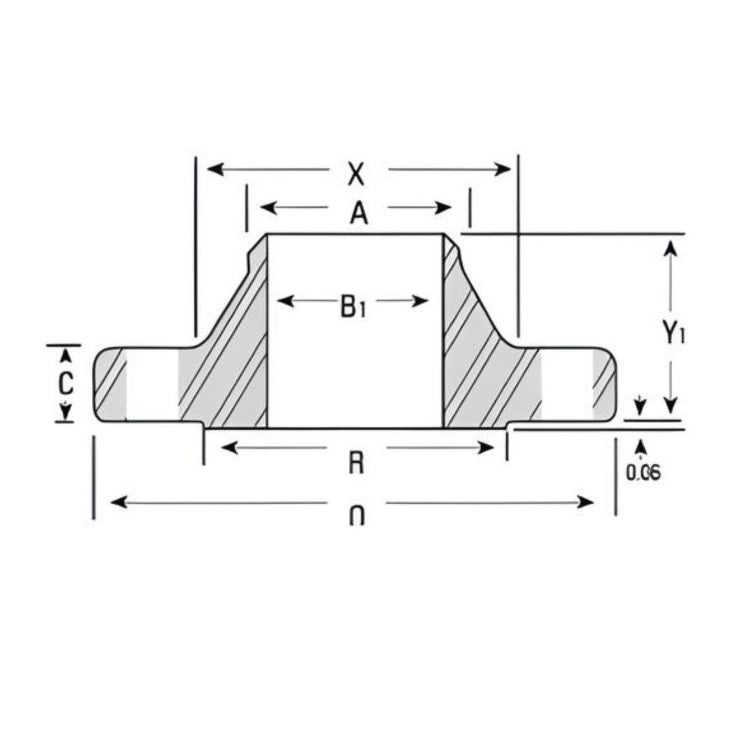

• Weld Neck Flanges: Provide a secure and leak-proof connection, ideal for high-pressure applications.

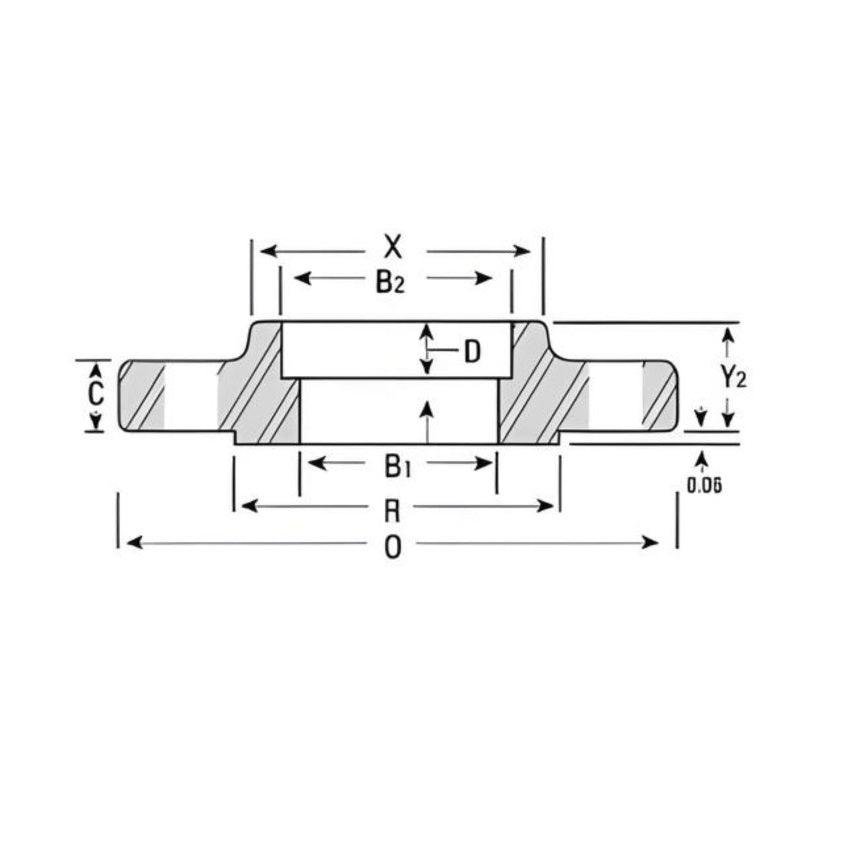

• Slip-On Flanges: Easy to install and suitable for low-pressure applications.

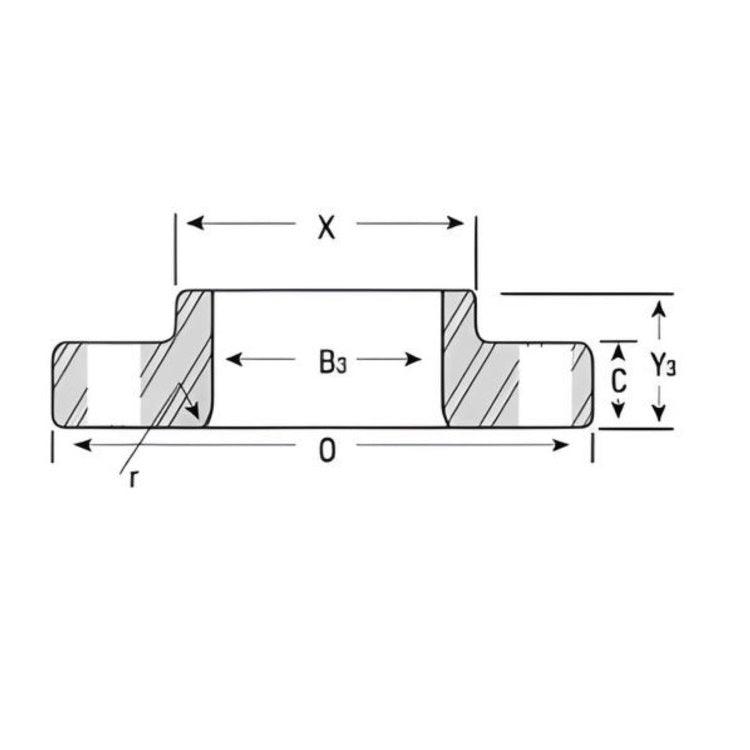

• Blind Flanges: Used to close the ends of pipes, valves, and pressure vessel openings.

• Socket Weld Flanges: Perfect for small-diameter, high-pressure pipes.

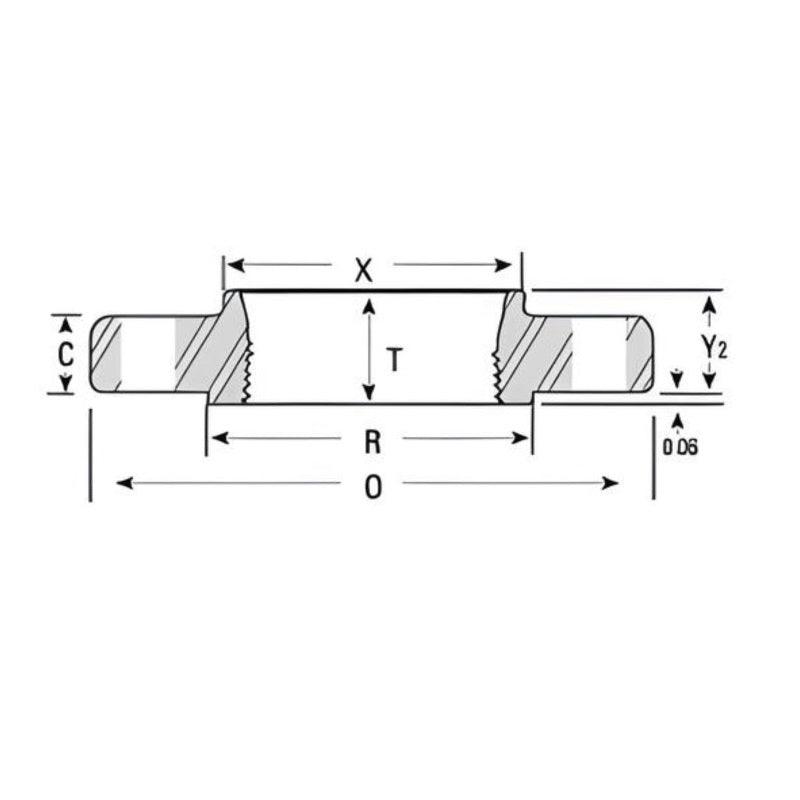

• Threaded Flanges: Used in systems where welding is not possible or practical.

Benefits of Stainless Steel Pipe Flanges

1. Corrosion Resistance: Stainless steel flanges are highly resistant to corrosion, making them ideal for use in harsh environments such as chemical processing plants and marine applications.

2. Durability: The robust nature of stainless steel ensures long-lasting performance, reducing the need for frequent replacements and maintenance.

3. High Temperature and Pressure Tolerance: These flanges can withstand extreme temperatures and pressures, making them suitable for a wide range of industrial applications.

4. Hygienic Properties: Stainless steel is easy to clean and maintain, making it perfect for applications in the food and beverage industry.

Applications of Stainless Steel Pipe Flanges

• Chemical Processing: Used in systems that handle corrosive chemicals, ensuring safe and reliable connections.

• Oil and Gas Industry: Essential for pipelines and equipment exposed to harsh environmental conditions.

• Food and Beverage Industry: Ideal for maintaining hygiene and preventing contamination in processing plants.

• Pharmaceutical Industry: Used in systems requiring high levels of cleanliness and corrosion resistance.

Manufacturing Standards

Stainless steel pipe flanges are manufactured according to various standards to ensure quality and performance:

• ASME B16.5: Standard for pipe flanges and flanged fittings.

• ASME B16.47: Standard for large diameter steel flanges.

• MSS-SP44: Standard for steel pipeline flanges.

Conclusion

Stainless steel pipe flanges are indispensable in many industries due to their corrosion resistance, durability, and versatility. Whether in chemical processing, oil and gas, or food and beverage industries, these flanges provide reliable and long-lasting connections that meet the demands of high-pressure and high-temperature environments.