Benefits of Sanitary Screen Gaskets

1. Particle Filtration: The mesh screen effectively filters out contaminants, ensuring that only clean fluids pass through.

2. Compliance with Standards: Made from FDA-compliant materials, these gaskets meet stringent hygiene and safety standards.

3. Durability: Constructed from high-quality materials like stainless steel and FDA-compliant elastomers, sanitary screen gaskets are designed to withstand rigorous cleaning and sterilization processes.

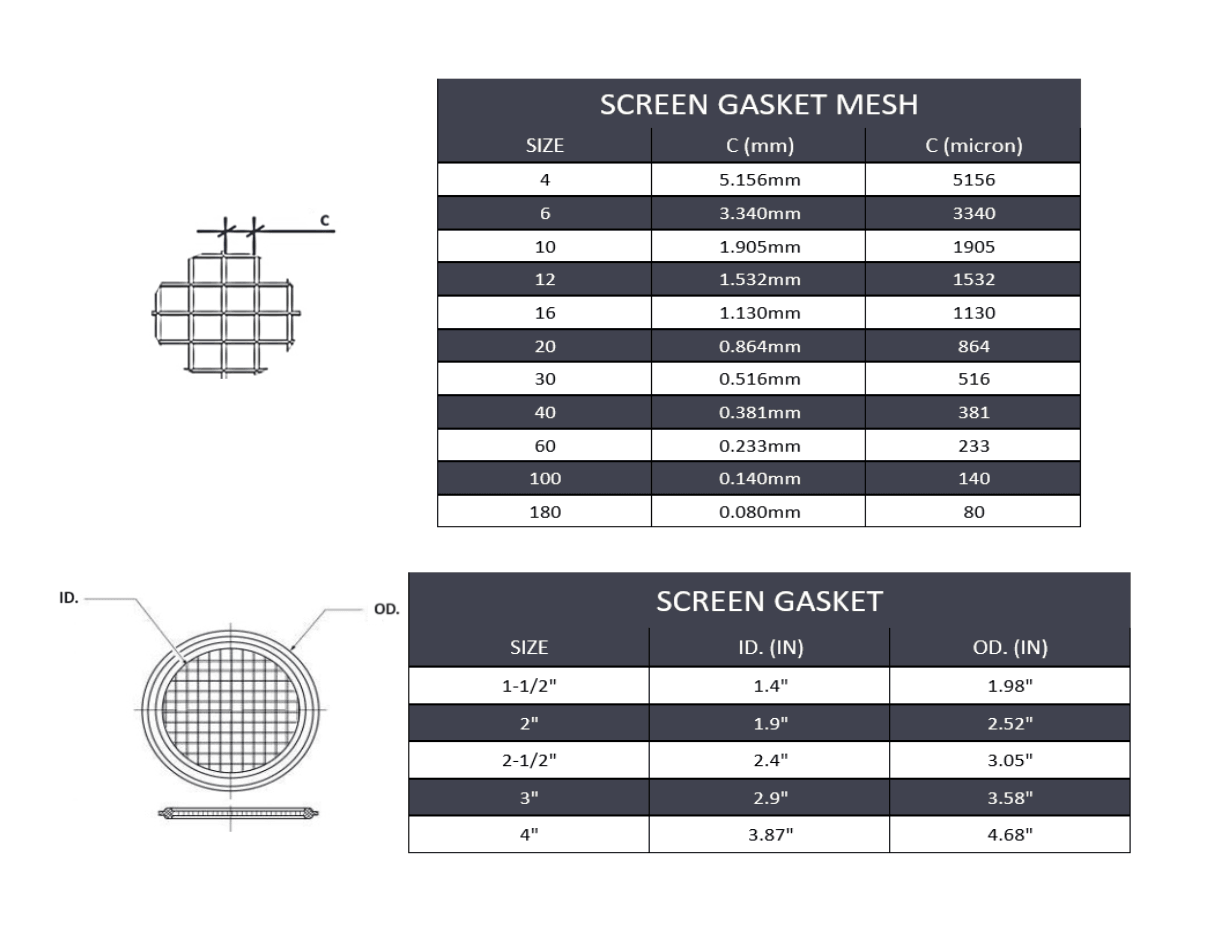

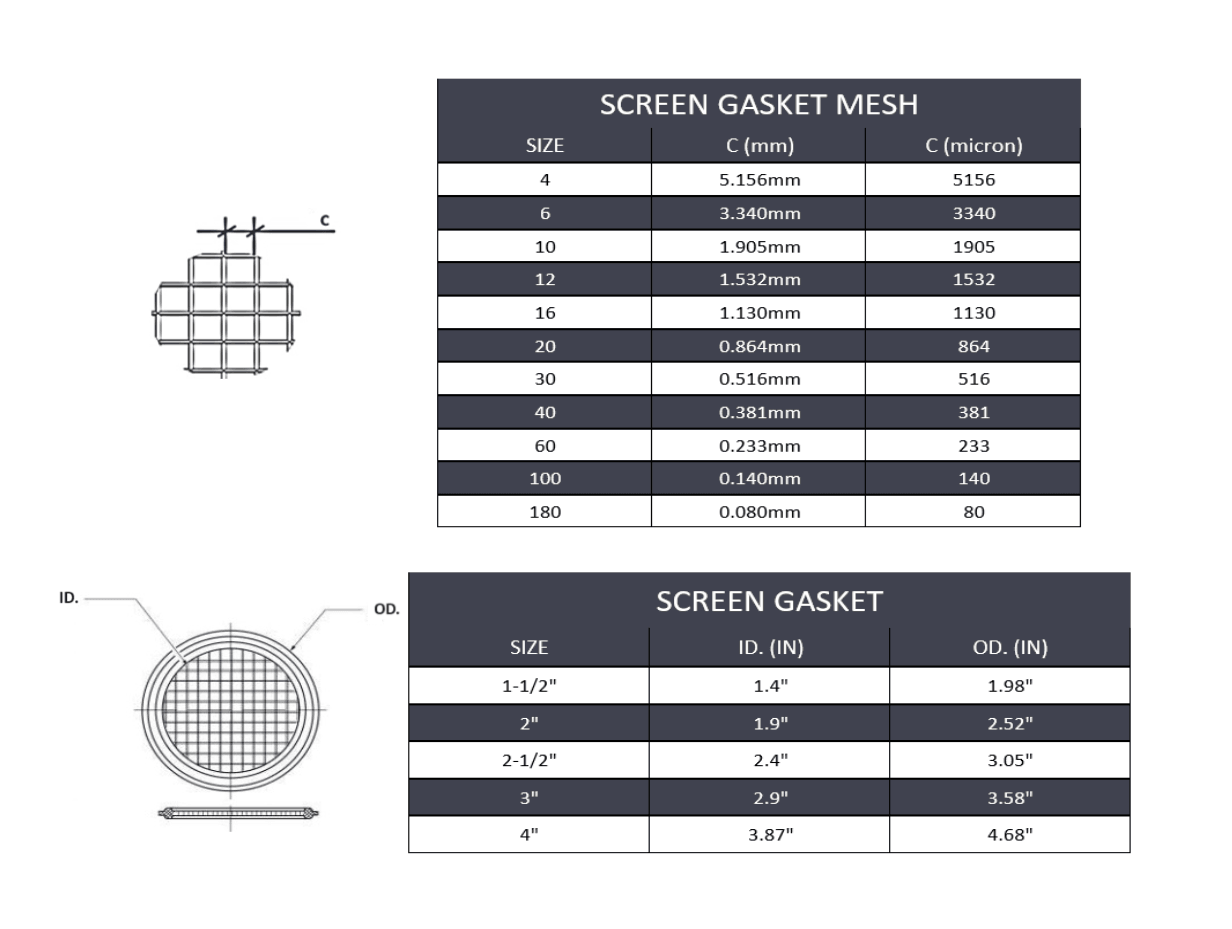

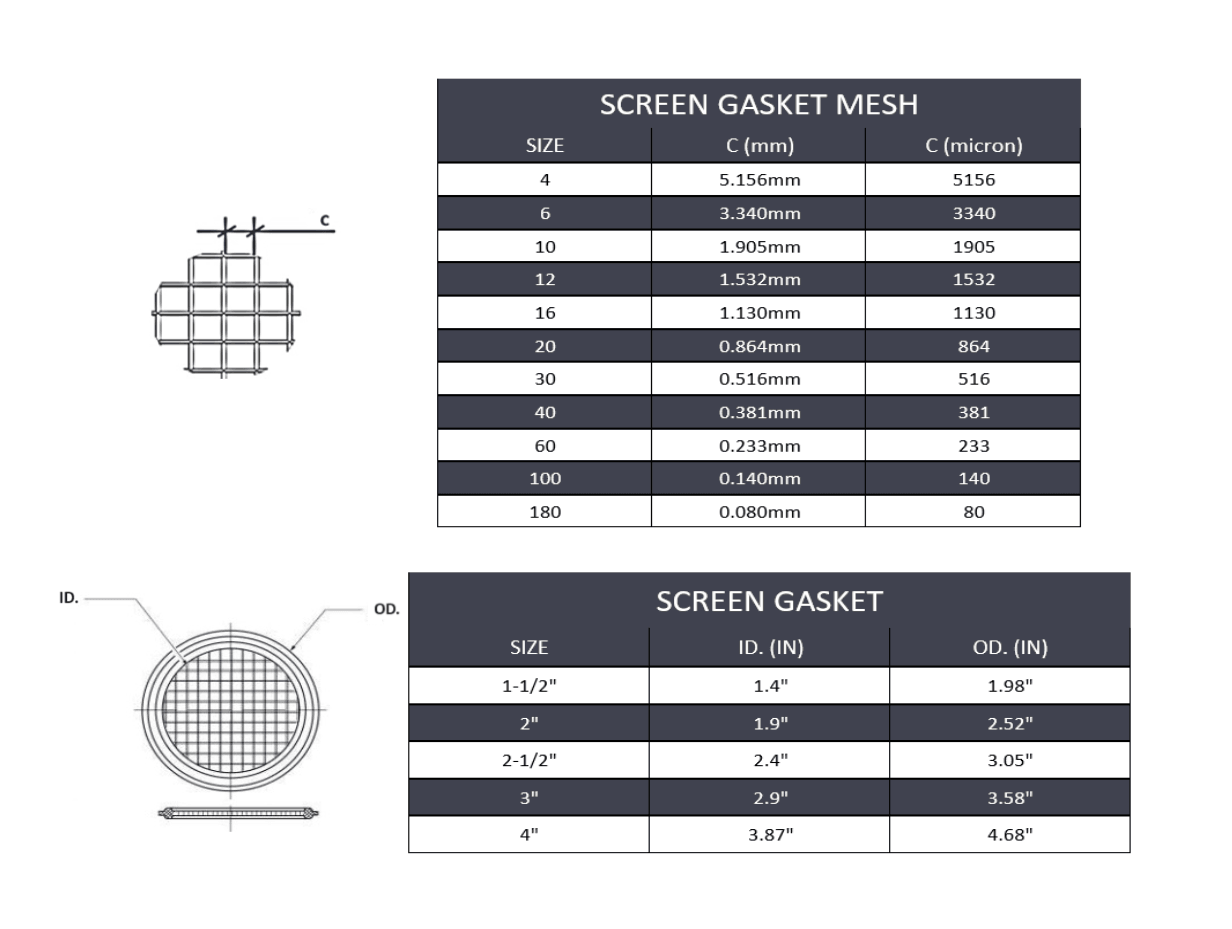

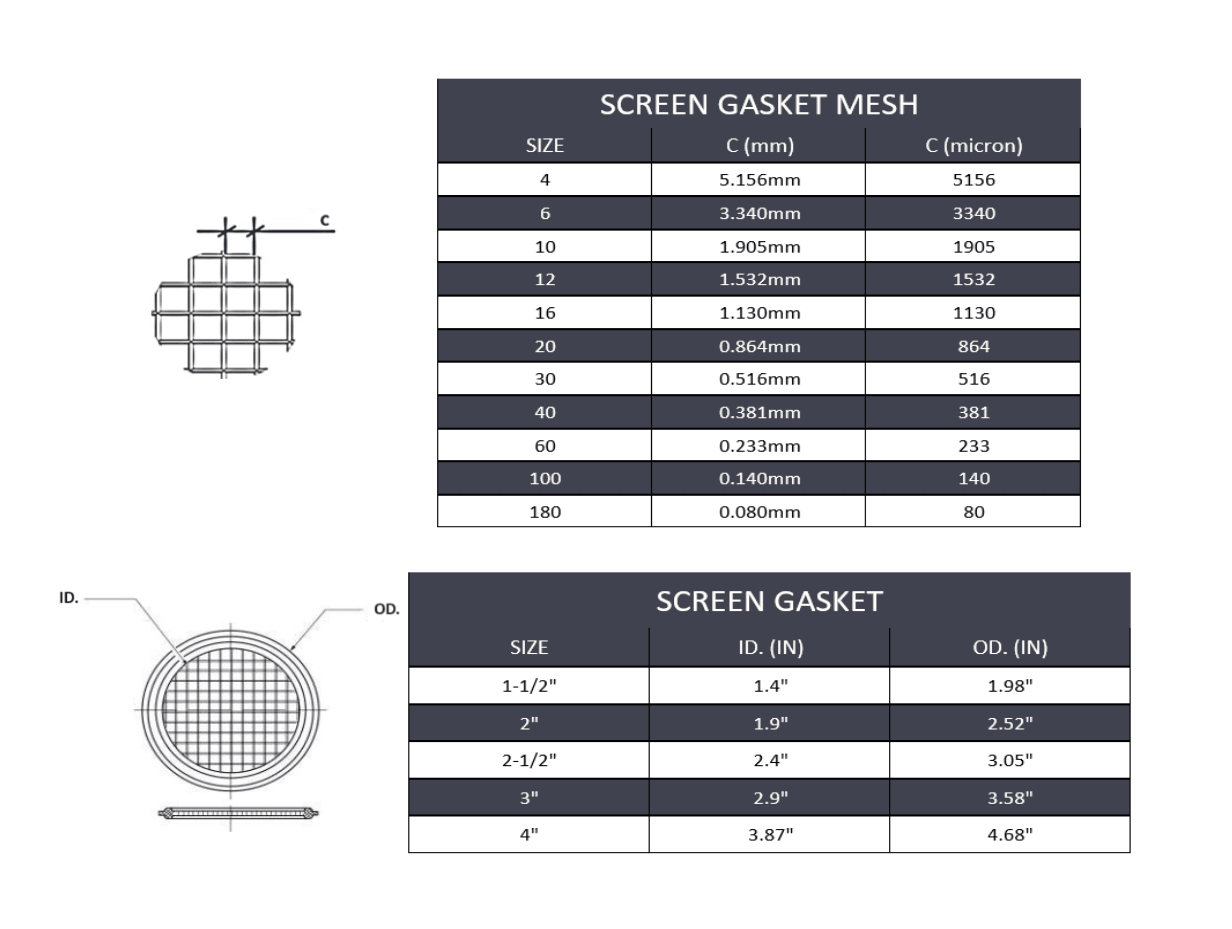

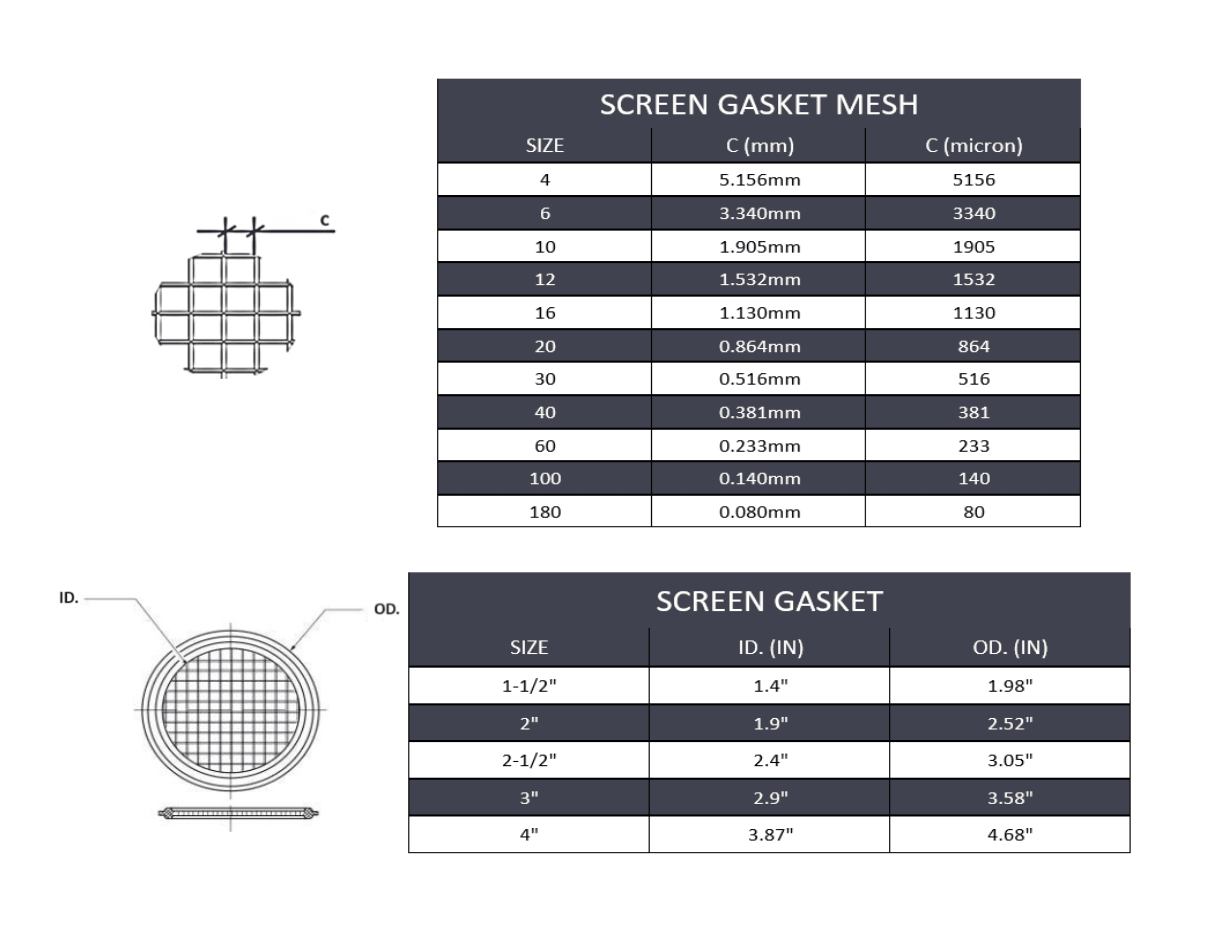

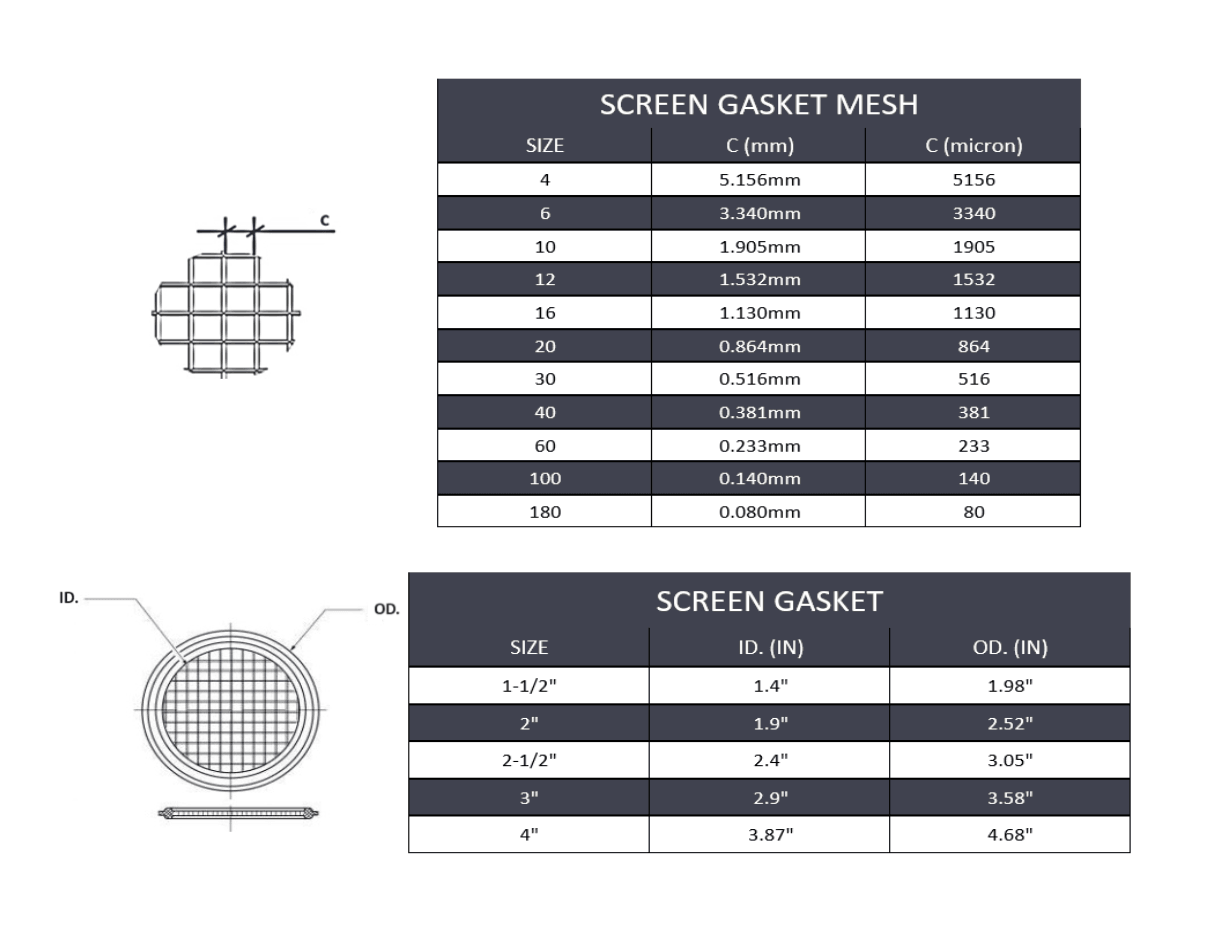

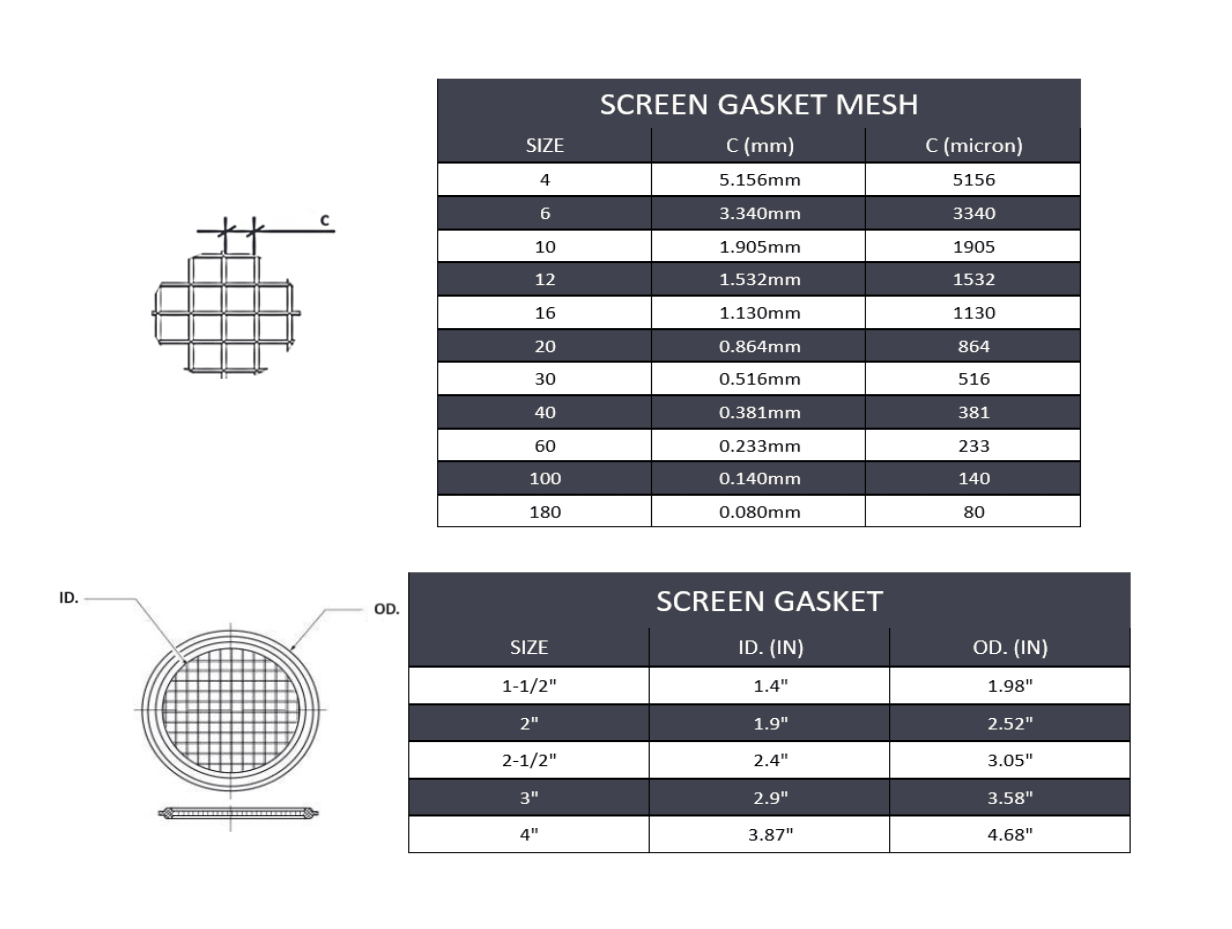

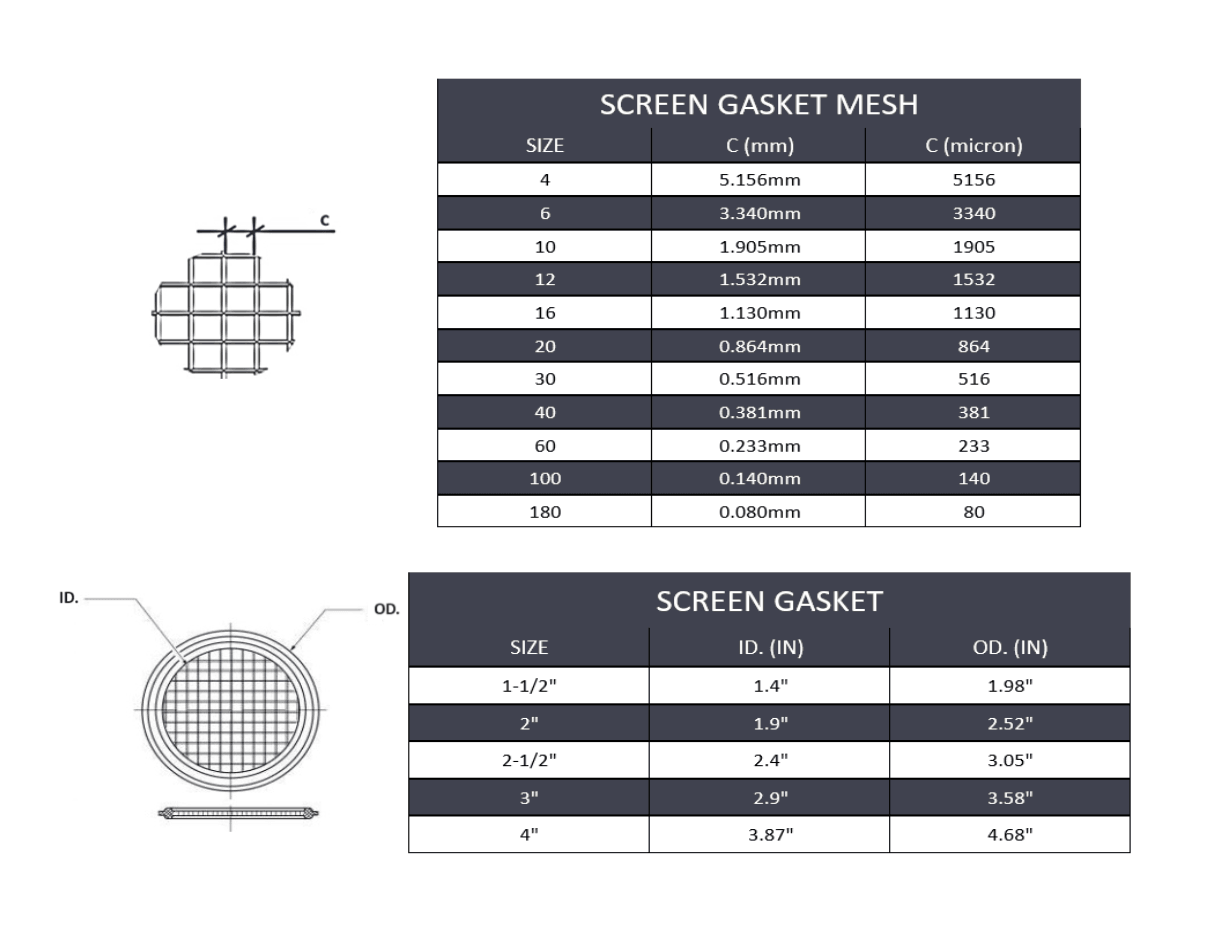

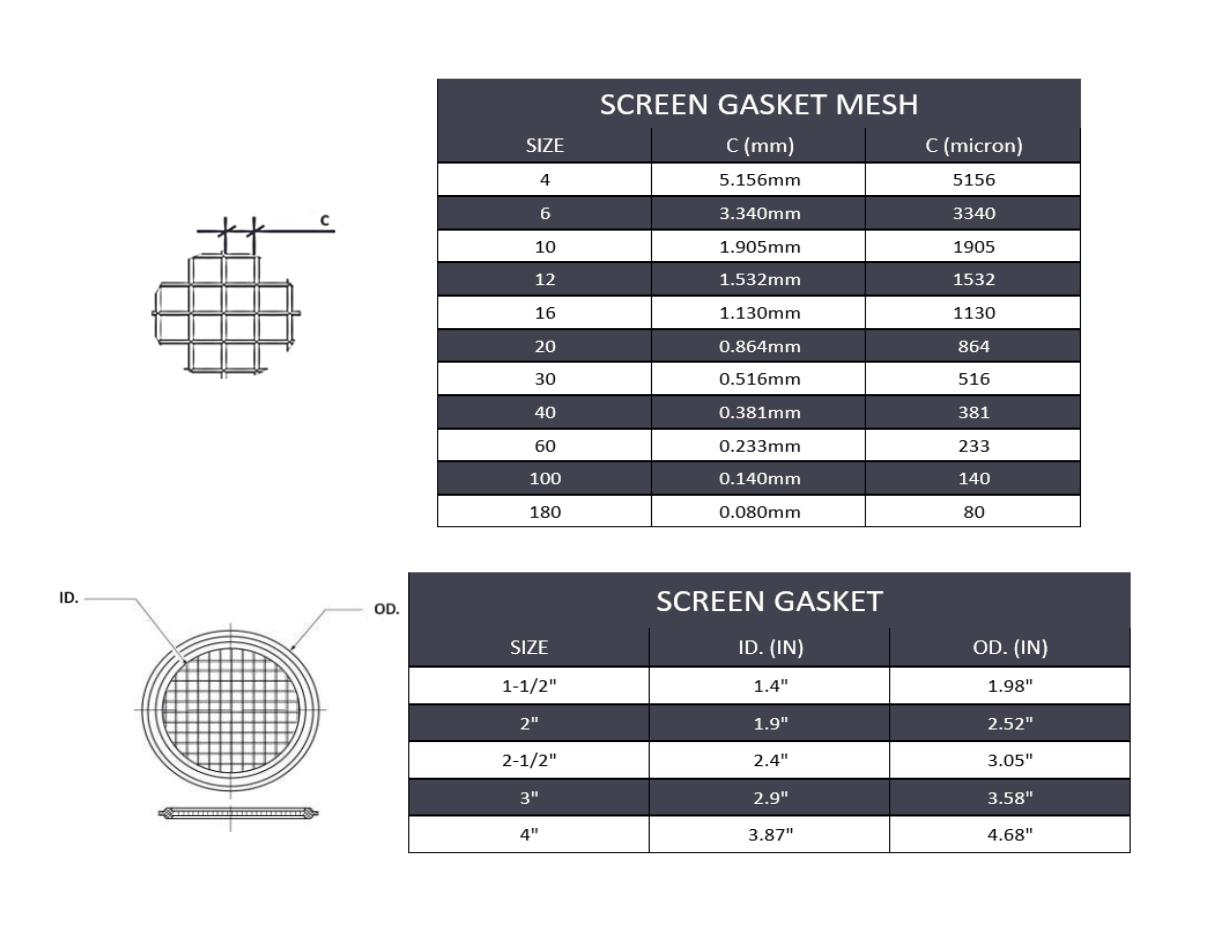

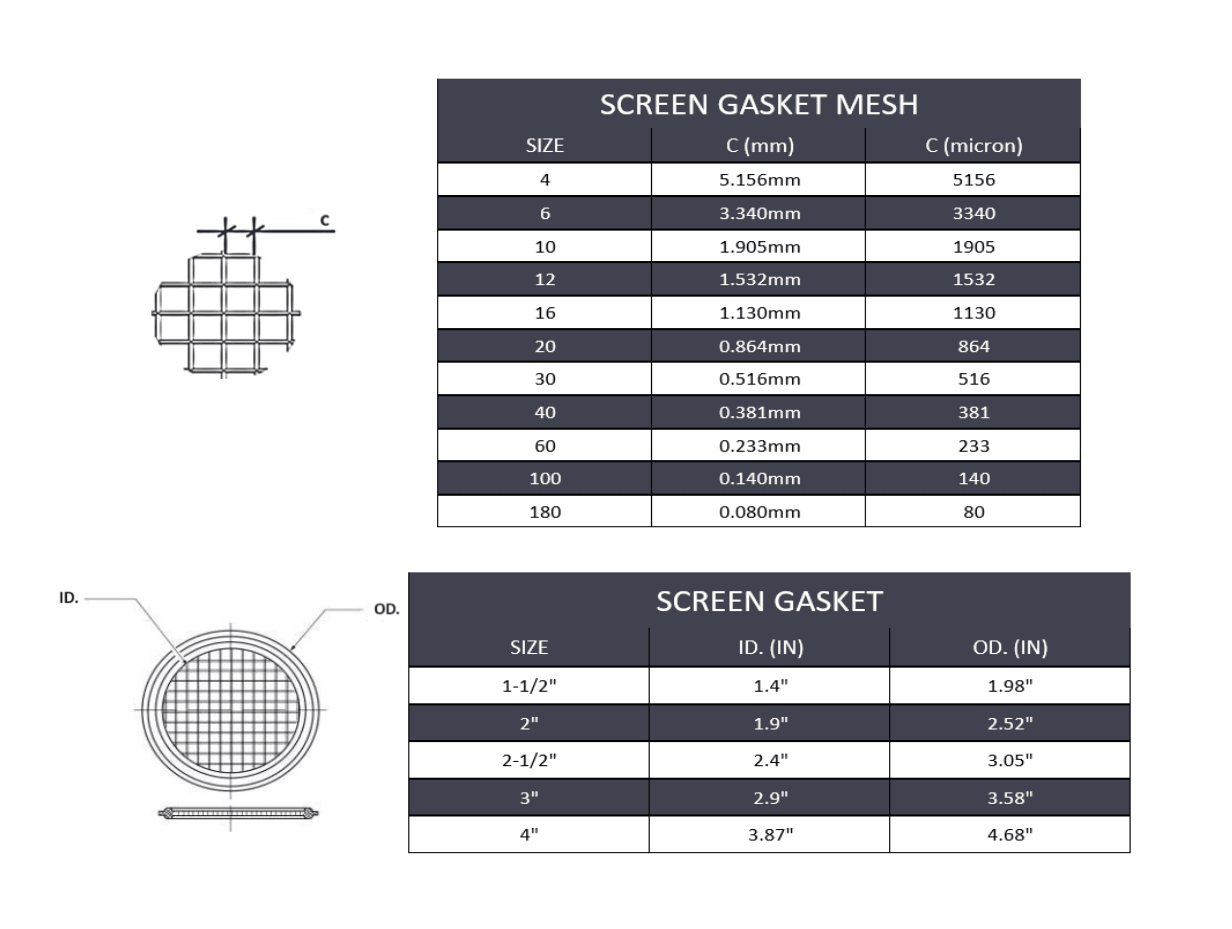

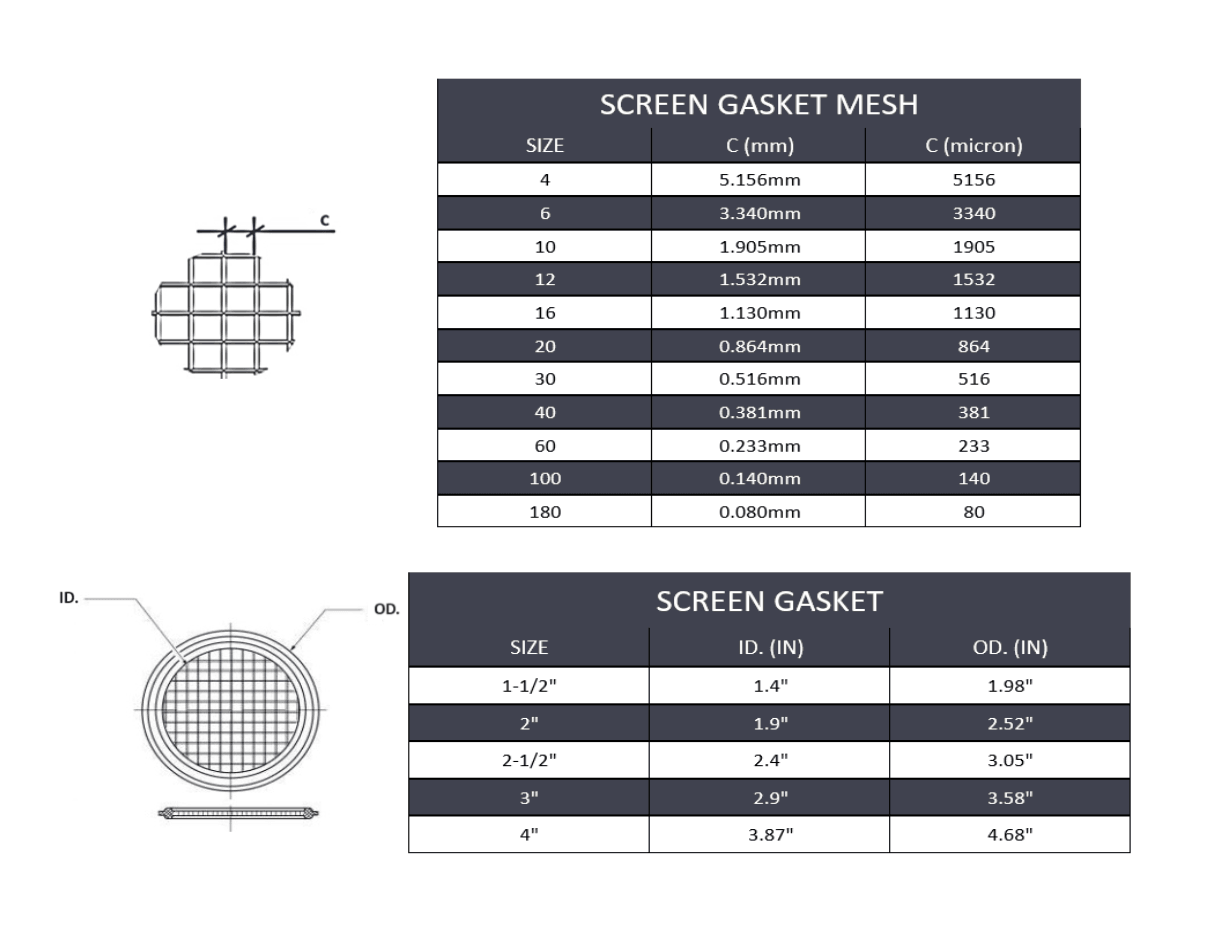

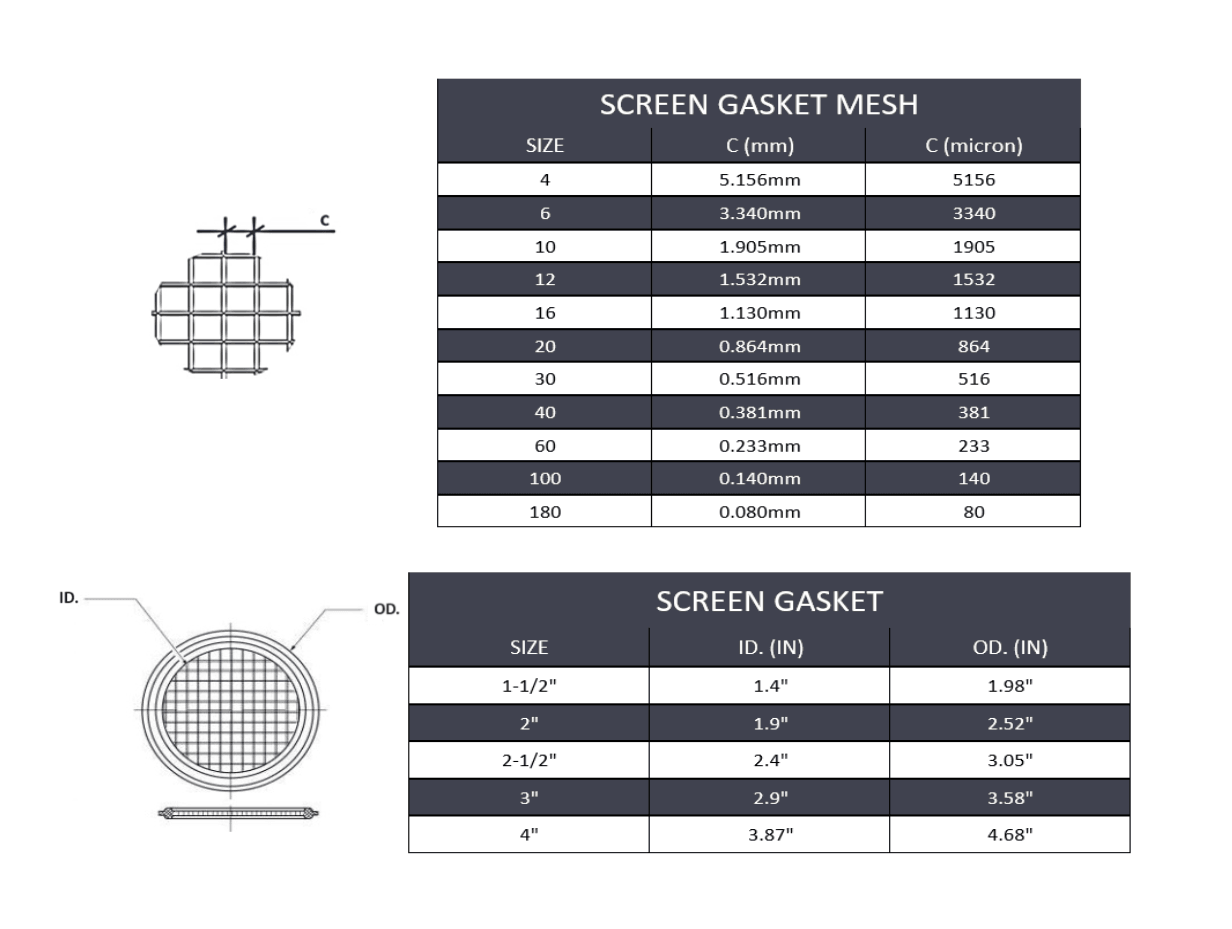

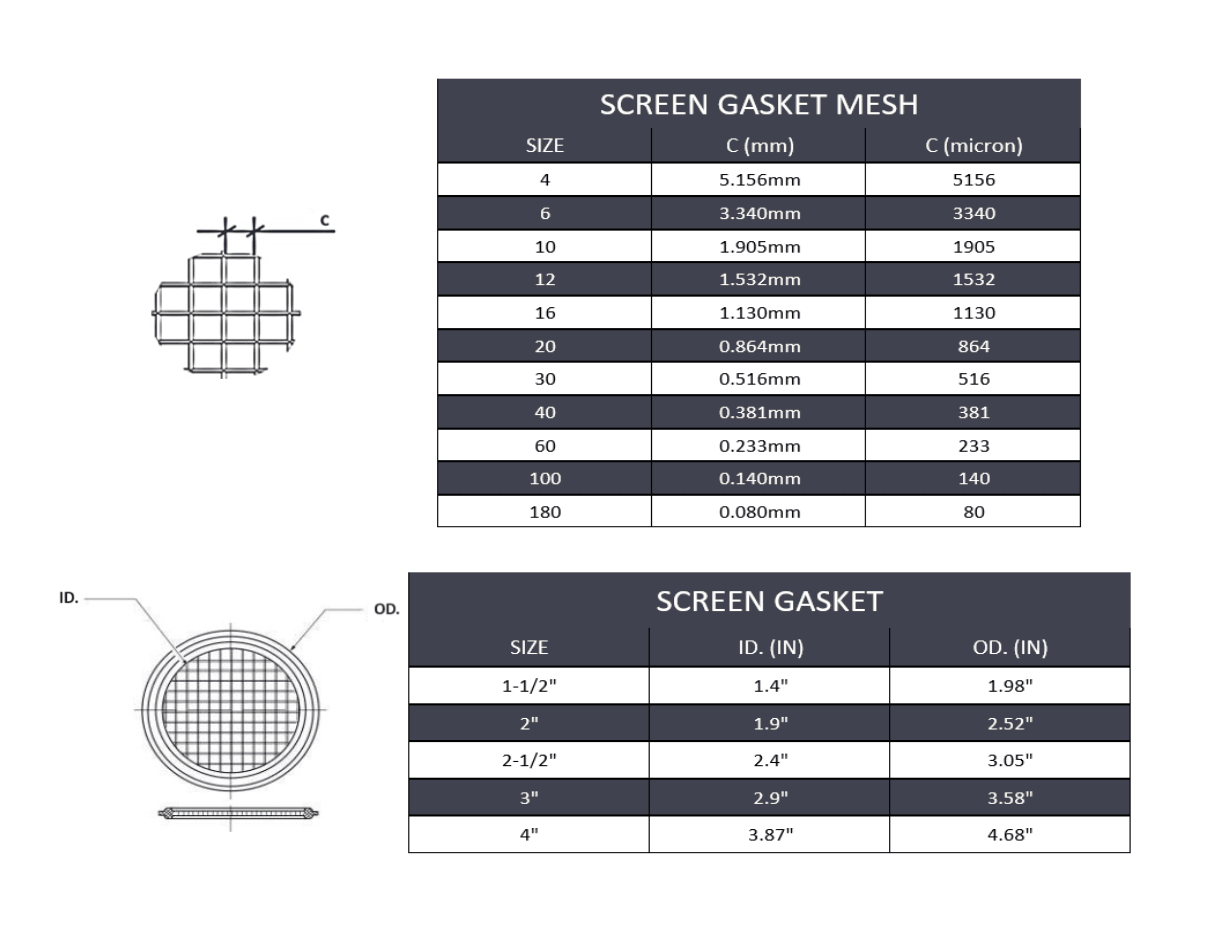

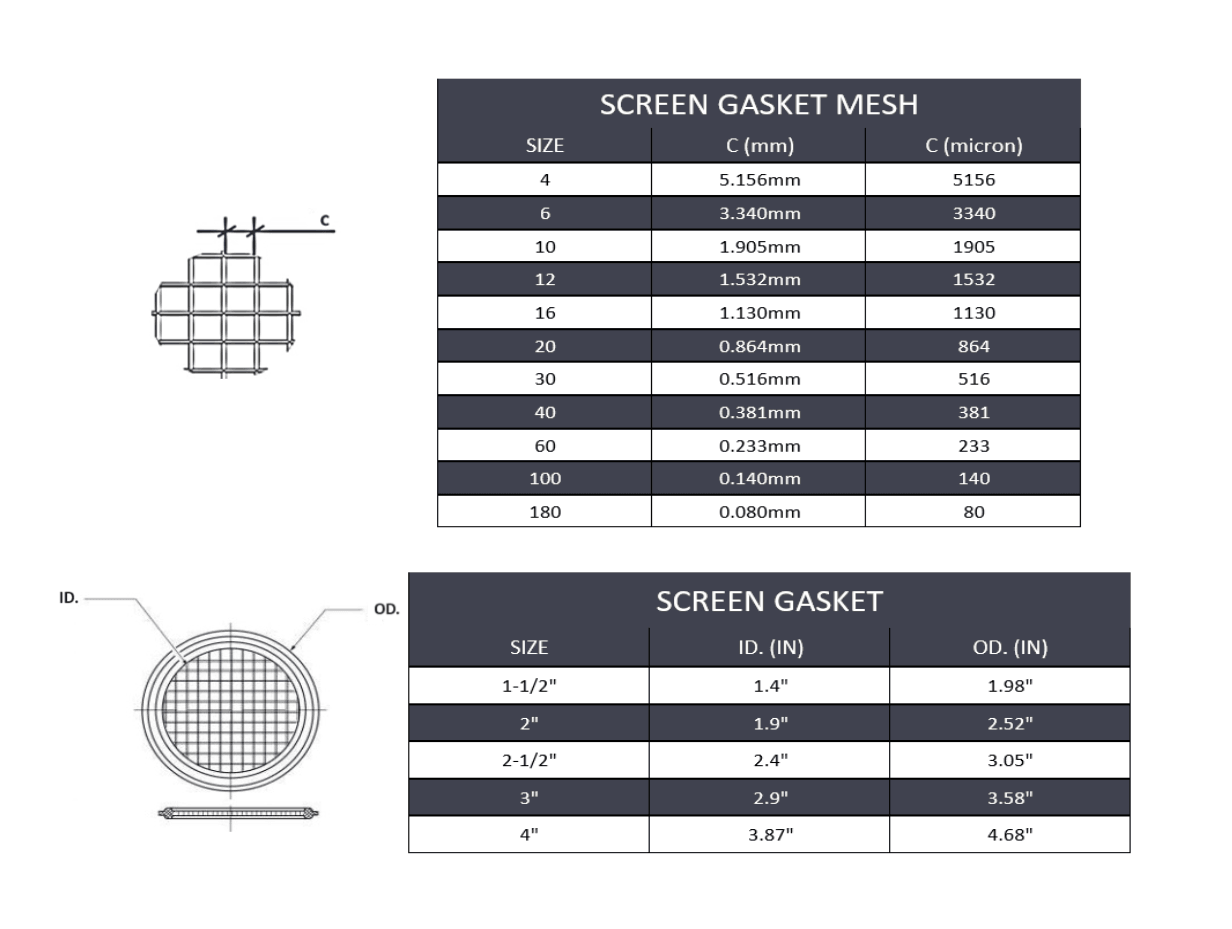

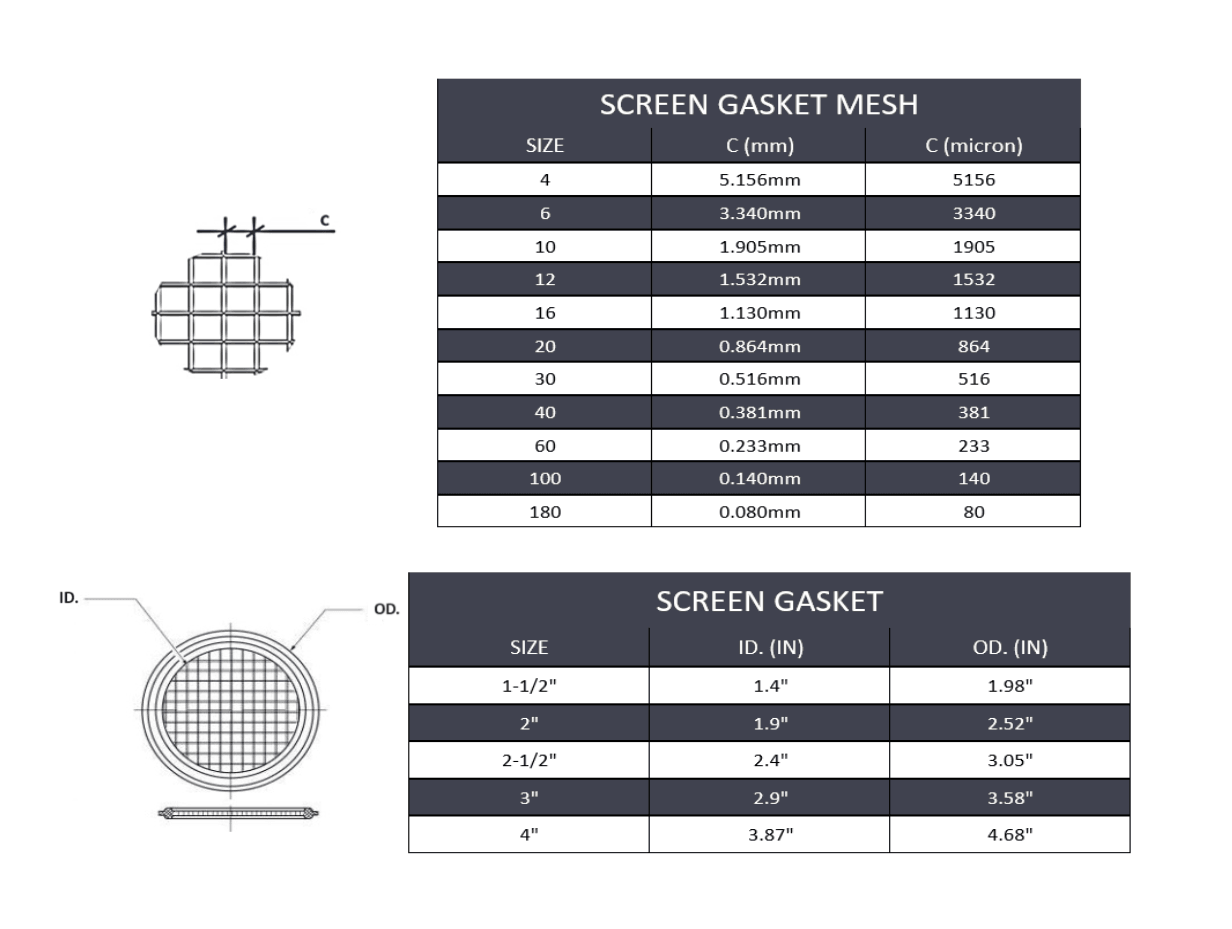

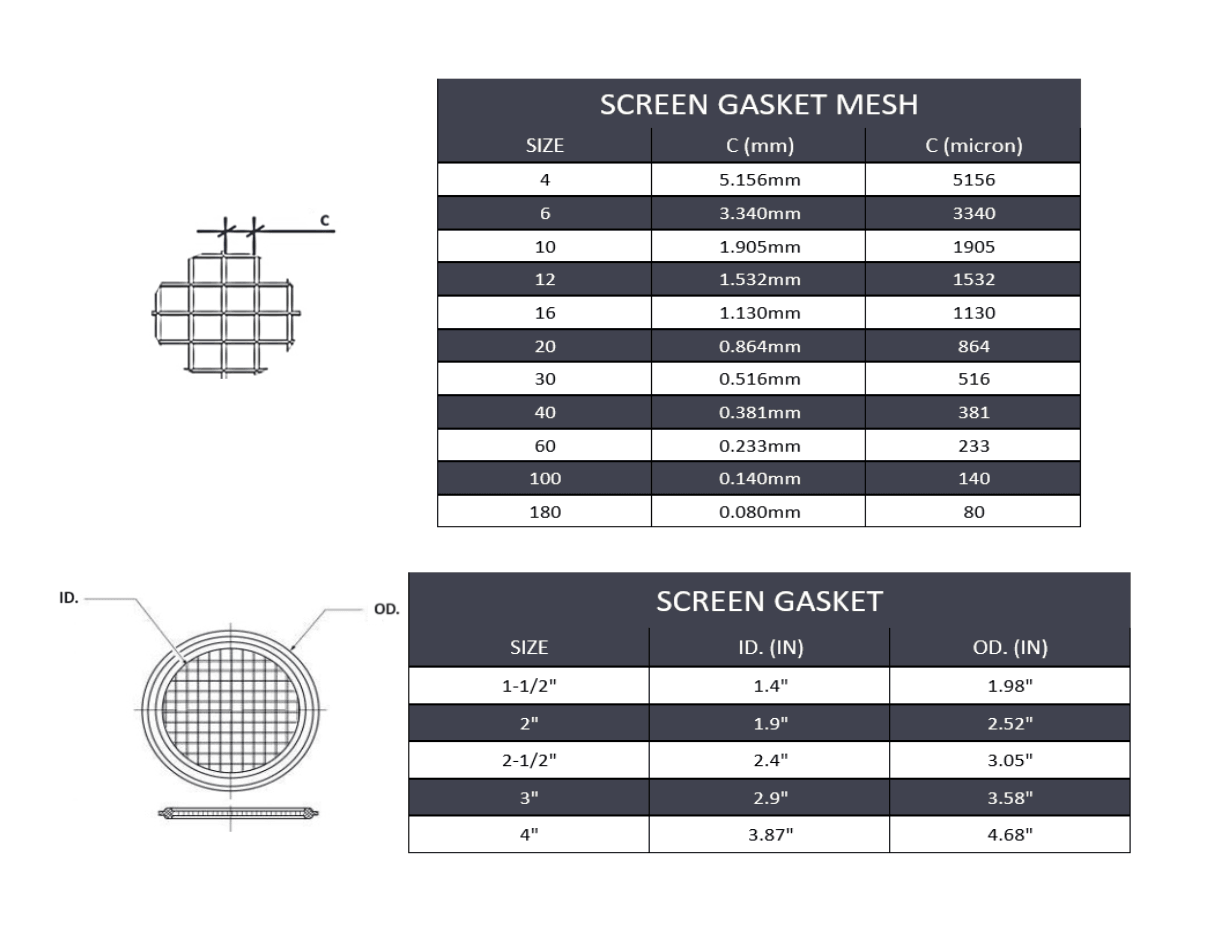

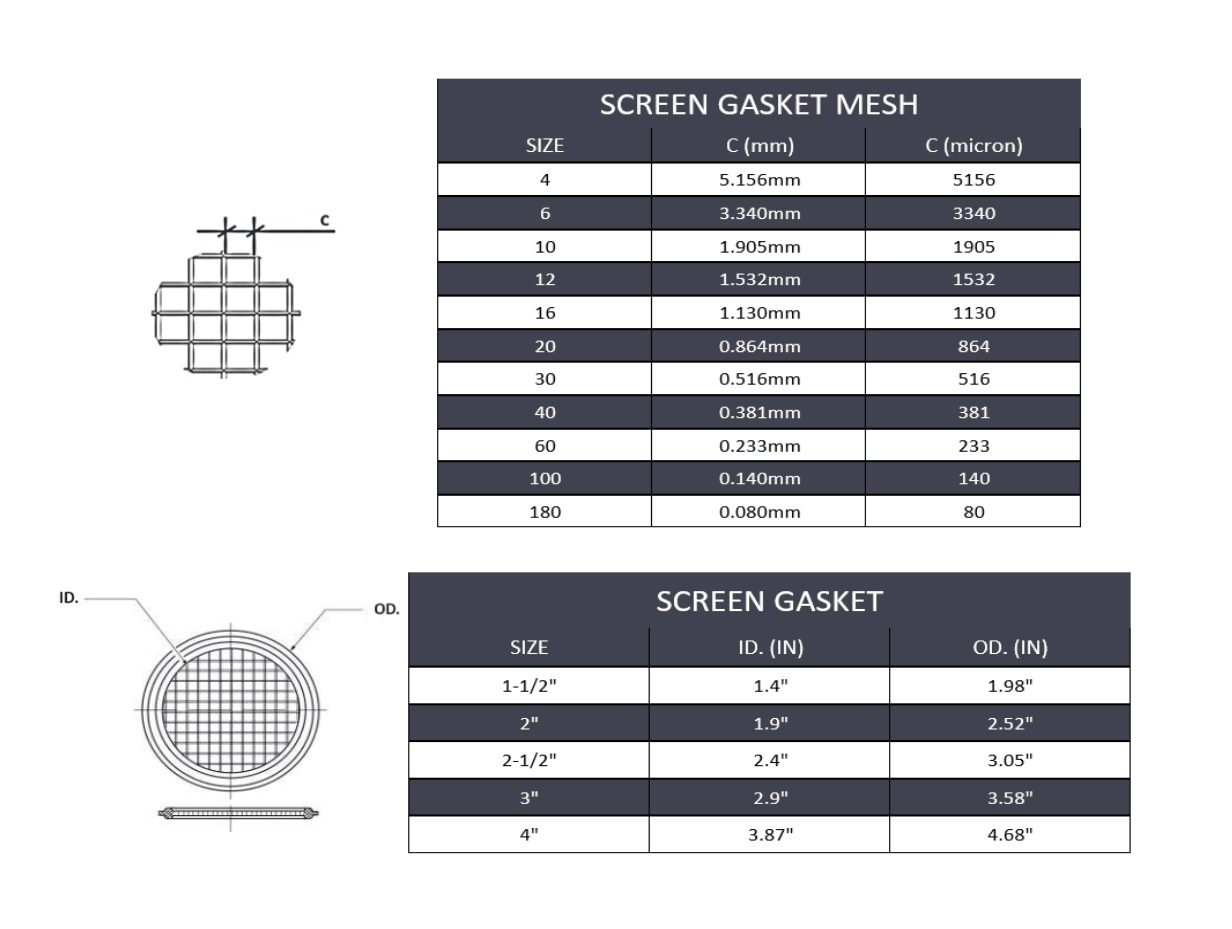

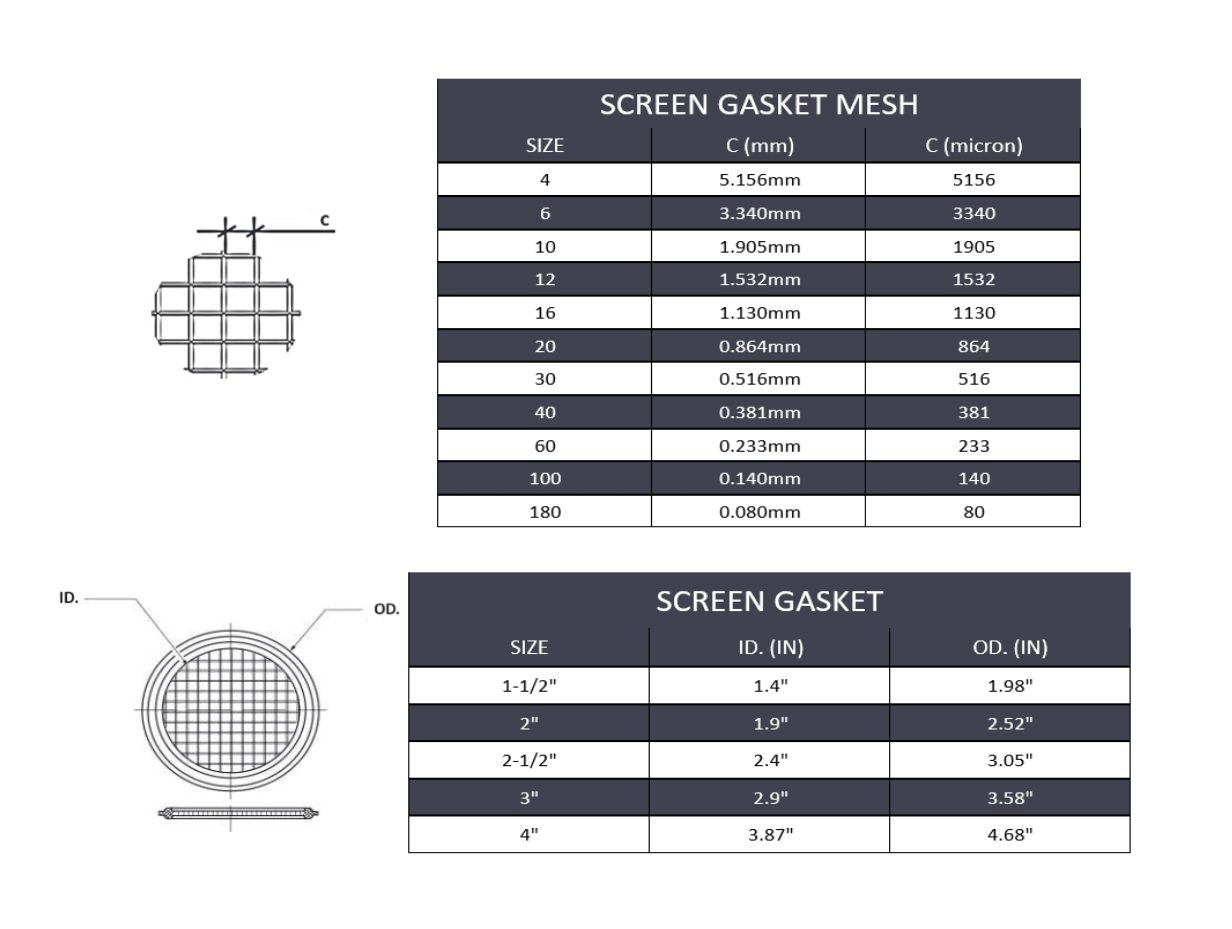

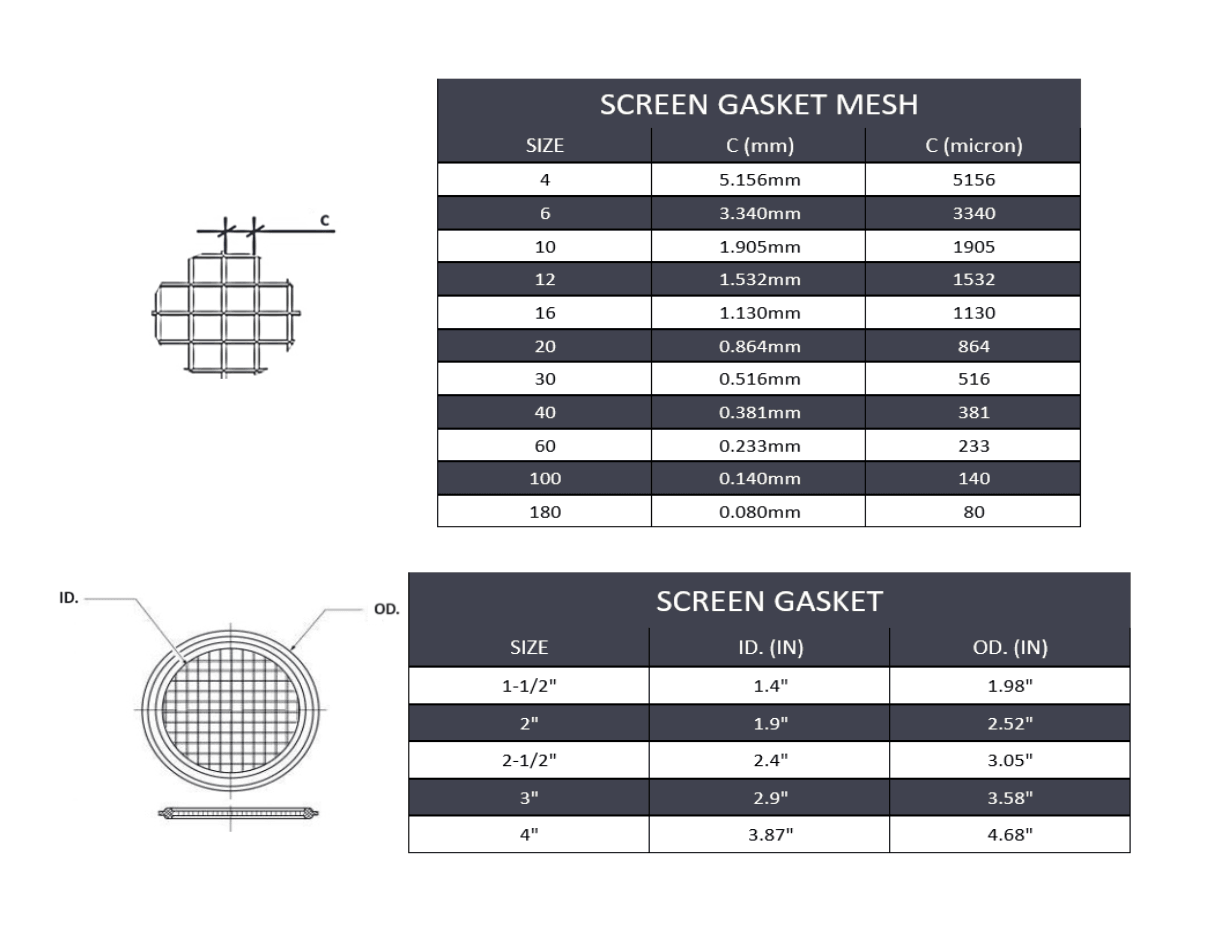

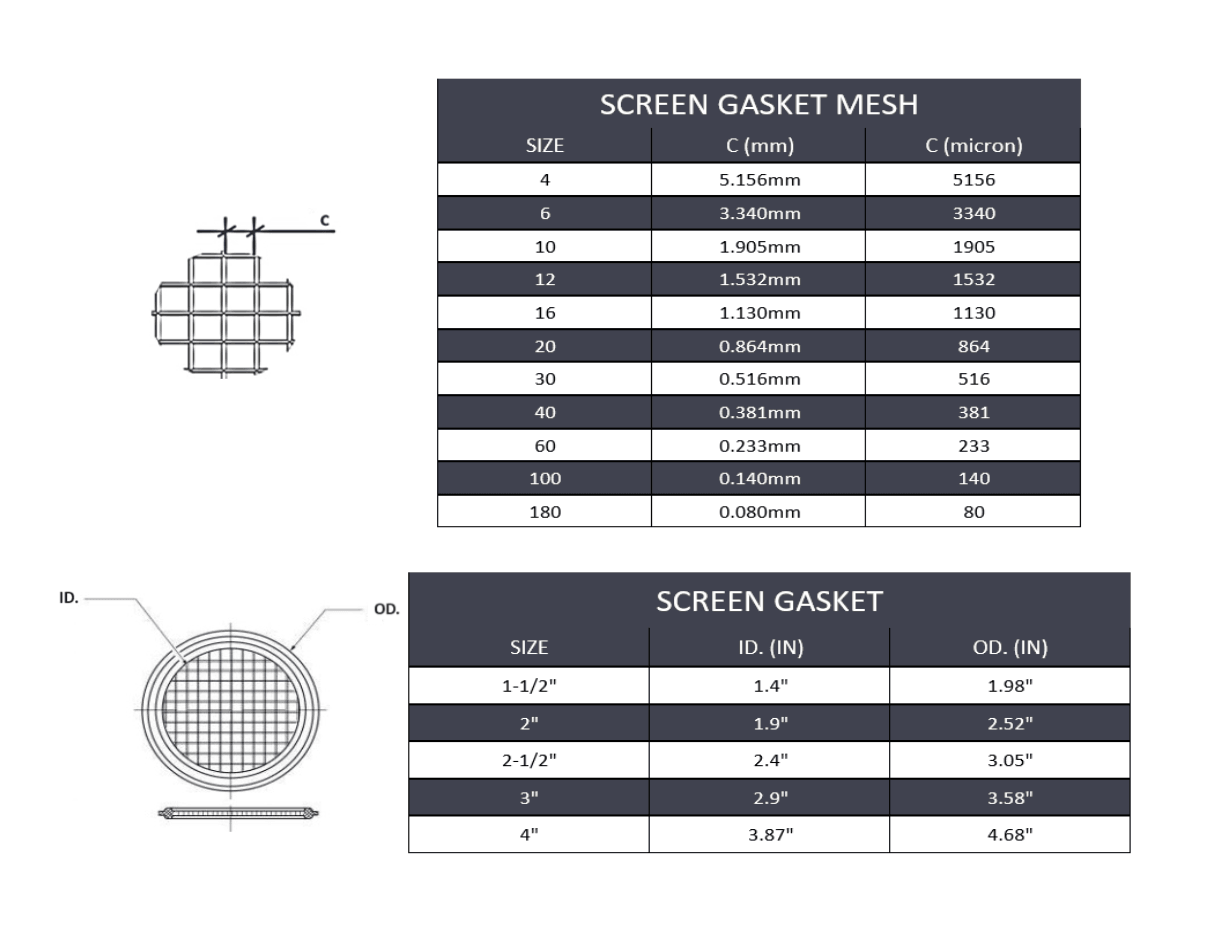

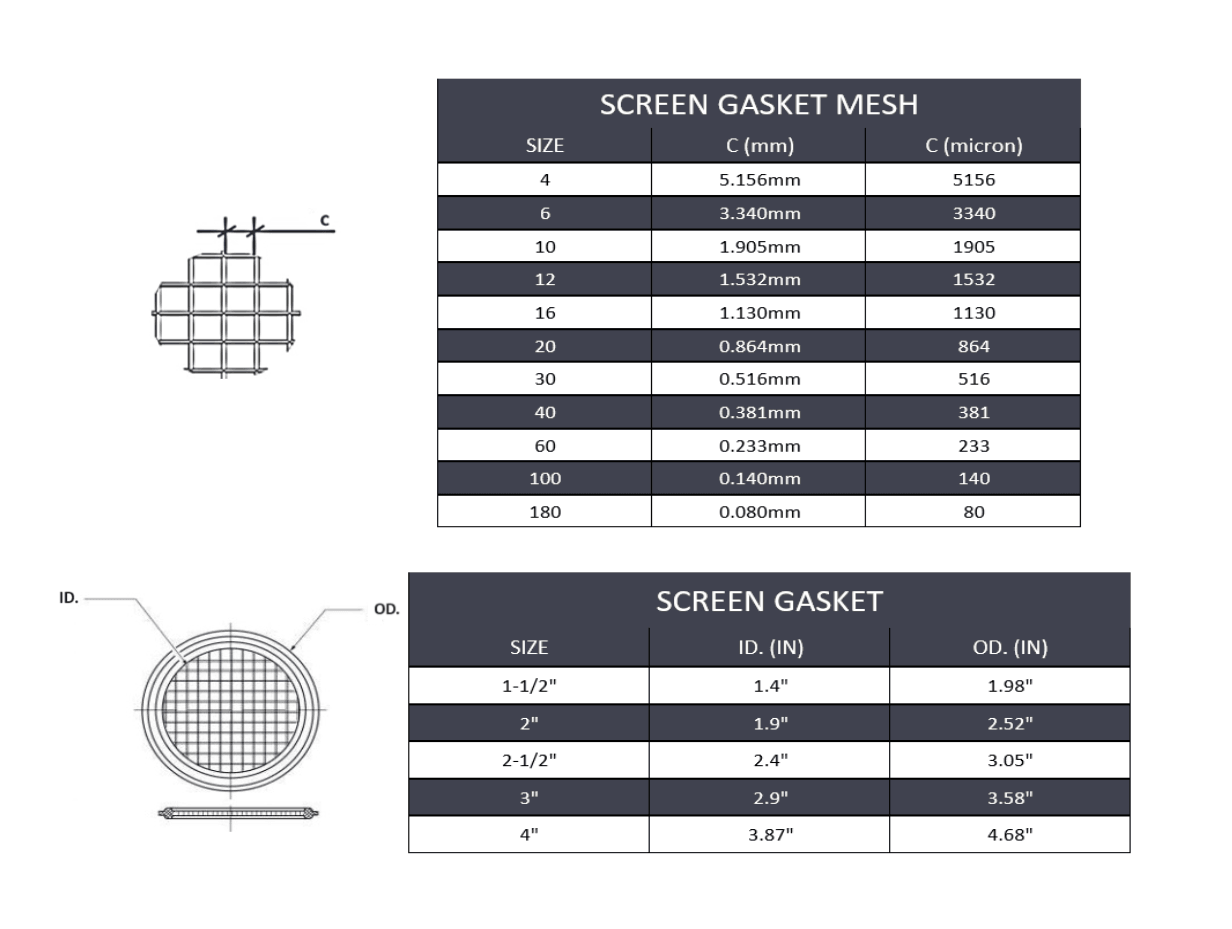

4. Versatility: Available in various sizes and mesh configurations, they can be customized to meet specific application requirements.

Applications of Sanitary Screen Gaskets

• Food and Beverage Industry: Used in processing lines to ensure product purity and prevent contamination.

• Pharmaceutical Industry: Essential for maintaining sterile conditions in drug manufacturing processes.

• Biotechnology: Used in bioprocessing to filter out impurities and ensure the integrity of biological products.

• Dairy Industry: Employed in milk and dairy product processing to maintain high hygiene standards.

Manufacturing Standards

Sanitary screen gaskets are manufactured according to various standards to ensure quality and performance:

• FDA Compliance: Materials used in these gaskets meet FDA requirements for food contact.

• USP Class VI: Some gaskets are made from materials that comply with USP Class VI standards for biocompatibility.

Conclusion

Sanitary screen gaskets are crucial for ensuring clean and efficient fluid processing in various industries. Whether in food and beverage, pharmaceuticals, or biotechnology, these gaskets provide reliable filtration and contamination control, meeting the highest standards of hygiene and safety.