Sanitary Ball Valves FAQ

Sanitary ball valves are specialized valves designed for use in applications where hygiene and cleanliness are paramount. These valves feature a spherical disc, the ball, which controls the flow of liquids and gases. When the ball's hole is aligned with the flow, the valve is open, and when it is perpendicular, the valve is closed. Made from high-quality materials such as stainless steel, sanitary ball valves are easy to clean and maintain, making them ideal for use in industries requiring stringent sanitary standards.

Sanitary ball valves are used in a variety of applications across several industries, including:

- Food and Beverage: To control the flow of ingredients and products in processing lines, ensuring hygiene and preventing contamination.

- Pharmaceuticals: To regulate the flow of fluids and gases in drug manufacturing processes, maintaining sterile conditions.

- Biotechnology: For precise control of fluids in bioprocessing applications, ensuring the integrity and purity of biologics.

- Dairy Industry: To handle the flow of milk and other dairy products, preventing contamination and ensuring product safety.

- Cosmetics: To manage the flow of raw materials and finished products in the production of cosmetics, maintaining high hygiene standards.

Their ability to provide reliable and sanitary fluid control makes these valves essential in many critical applications.

Sanitary ball valves operate by using a spherical ball to control the flow of fluids or gases. Here’s how they function:

- Open Position: When the valve handle is turned so that the ball's hole is aligned with the flow direction, the valve is open, allowing fluid to pass through.

- Closed Position: Turning the handle 90 degrees rotates the ball so that the hole is perpendicular to the flow direction, closing the valve and stopping the flow.

- Sealing: The ball fits tightly within the valve body, often using seals made of materials like PTFE, to prevent leaks and ensure a hygienic seal.

- Hygiene: The smooth surfaces and minimal internal cavities of sanitary ball valves reduce the risk of contamination and make them easy to clean.

This mechanism allows for efficient and reliable control of fluid flow while maintaining high sanitary standards.

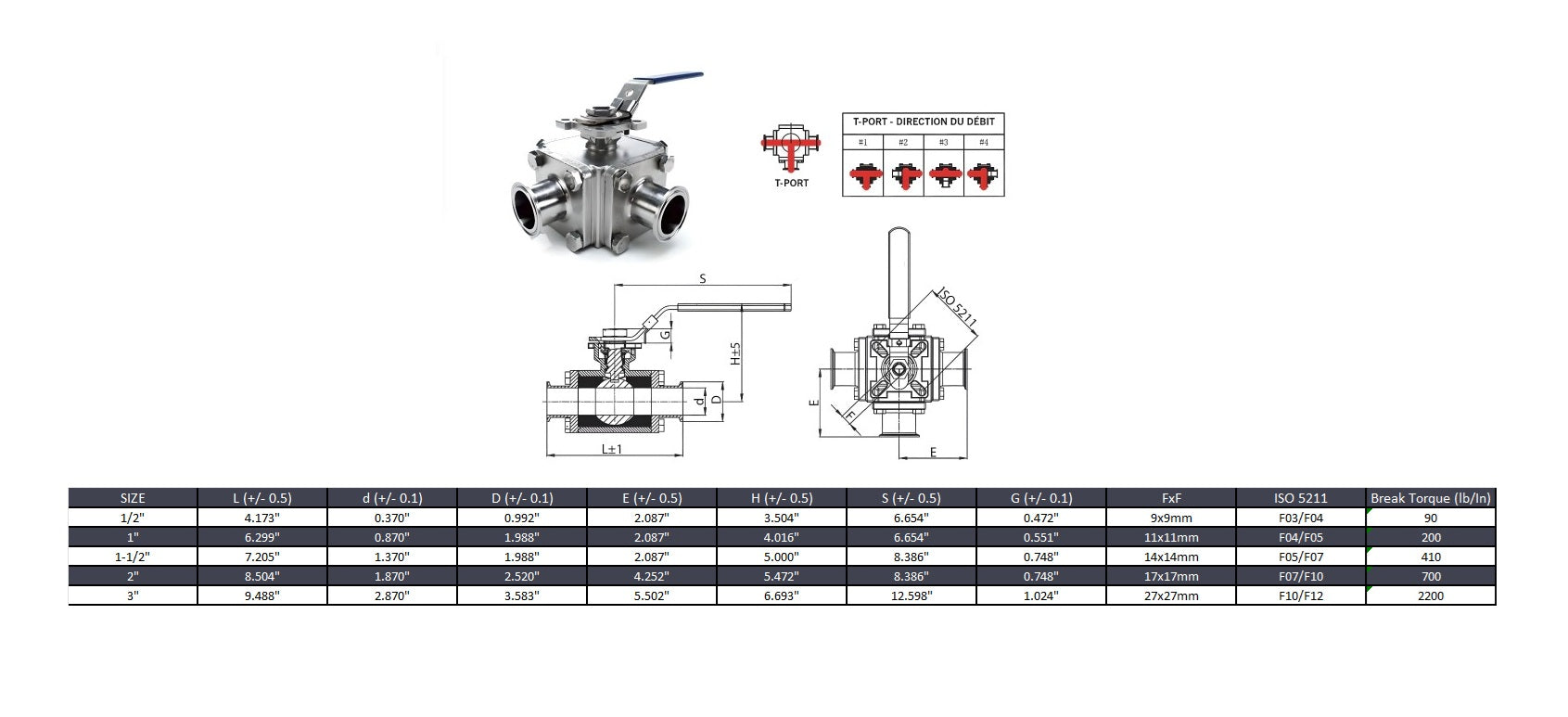

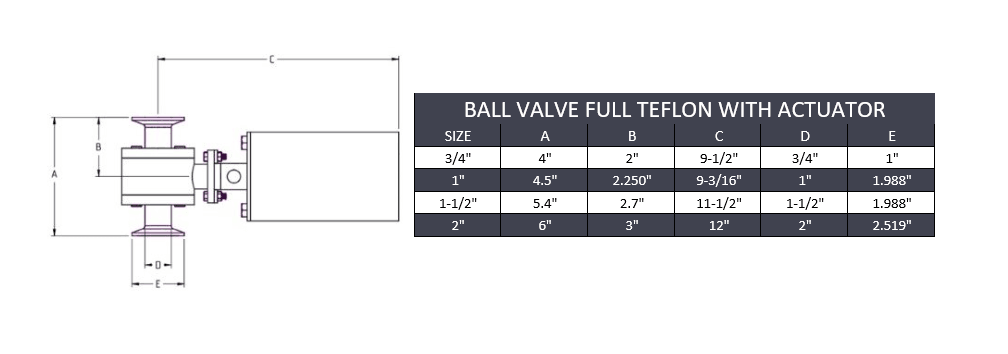

Sanitary ball valves are manufactured using high-quality materials and precision engineering to ensure durability, reliability, and hygiene. The typical manufacturing process involves:

- Material Selection: High-grade stainless steel is commonly used for its corrosion resistance, strength, and ease of cleaning.

- Forging and Machining: The raw materials are forged and machined into the components of the valve, ensuring precise dimensions and smooth surfaces.

- Polishing: The valve components are polished to a high finish to prevent bacterial growth and facilitate easy cleaning.

- Assembly: The ball, seals, and other components are assembled into the valve body, ensuring a tight fit and reliable operation.

- Testing: Each valve undergoes rigorous testing to ensure it meets industry standards for performance, hygiene, and durability.

- Certification: Many sanitary ball valves are certified to industry standards, such as 3-A or FDA, to guarantee their suitability for hygienic applications.

This careful manufacturing process ensures that our sanitary ball valves deliver optimal performance and reliability in demanding applications.