Filters (0)

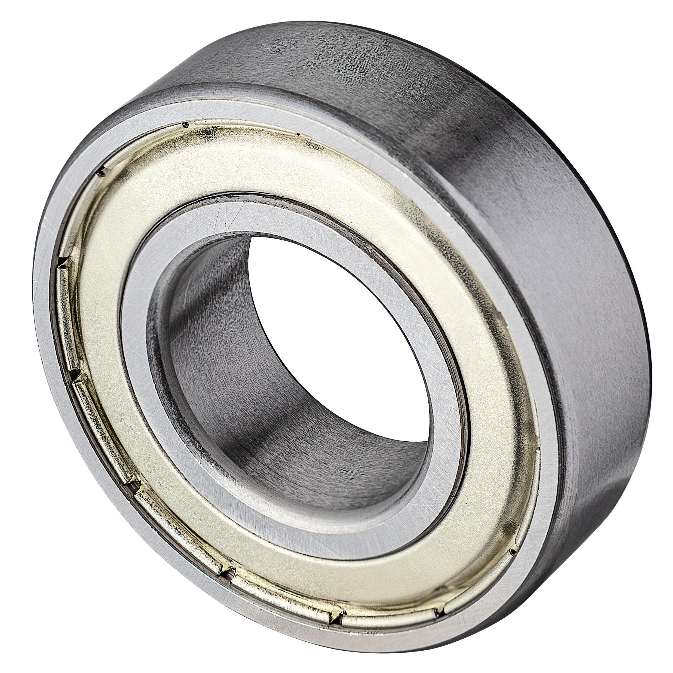

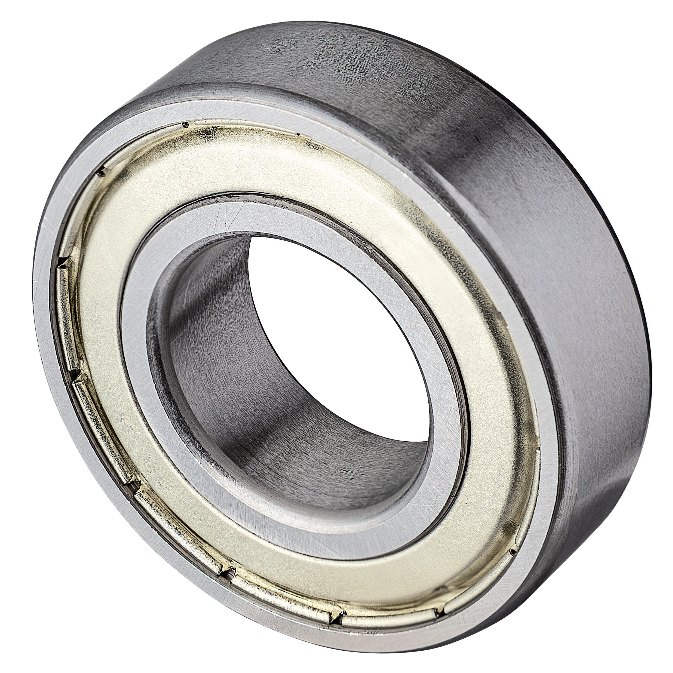

Ball Bearings are engineered to reduce friction and support rotational movement between moving parts. Featuring hardened steel or stainless steel construction, they provide smooth, reliable operation under radial and axial loads. Precision manufacturing ensures consistent performance, minimal wear, and extended service life. These bearings are versatile and compatible with a wide range of mechanical systems, delivering dependable operation in demanding environments.