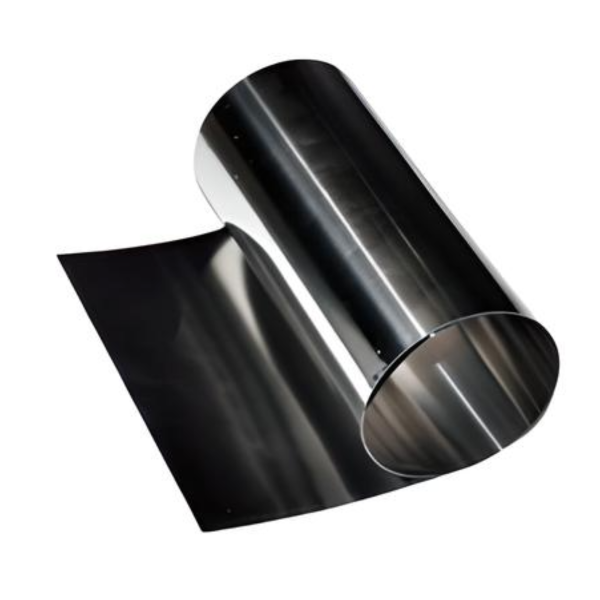

Shims and Shim Stock Rolls

Shim stock consists of thin, flat materials available in rolls or sheets, used to create custom shims for various industrial applications. These shims are essential for precise alignment, spacing, and leveling in machinery and equipment.

Advantages of Using Shim Stock

• Precision: Manufactured to exact thicknesses, ensuring accurate adjustments.

• Versatility: Available in various materials to suit different industrial needs.

• Ease of Use: Can be easily cut or stamped to the required shape and size.

• Cost-Effective: Reduces the need for custom-made parts, saving time and money.

• Durability: High-quality materials ensure long-lasting performance.

Applications of Shim Stock

• Machinery Alignment: Used to align and level machinery components.

• Tool and Die Setup: Essential for precise adjustments in tool and die manufacturing.

• Aerospace: Used in aircraft assembly for precise fitting and alignment.

• Automotive: Ensures proper spacing and alignment in vehicle assembly.

• Electronics: Provides insulation and spacing in electronic devices.

Types of Shim Stock

1. Stainless Steel Shim Stock: Known for its corrosion resistance and durability, ideal for harsh environments.

2. Brass Shim Stock: Offers excellent machinability and is often used in applications requiring non-magnetic properties.

3. Aluminum Shim Stock: Lightweight and corrosion-resistant, suitable for aerospace and automotive industries.

4. Plastic Shim Stock: Provides electrical insulation and is resistant to chemicals, used in electronics and chemical processing.

5. Copper Shim Stock: Excellent conductivity, used in electrical and thermal applications.

Choosing the Right Shim Stock

• Material: Select the appropriate material based on the application requirements (e.g., corrosion resistance, conductivity).

• Thickness: Ensure the shim stock is available in the required thickness for precise adjustments.

• Environmental Conditions: Consider the operating environment to choose the right material (e.g., temperature, chemical exposure).

Conclusion

Shim stock is a versatile and essential component in various industrial applications, providing precision, durability, and cost-effectiveness. Selecting the right shim stock can enhance the performance and longevity of your machinery and equipment.