Benefits of Forged Steel Pipe Flanges

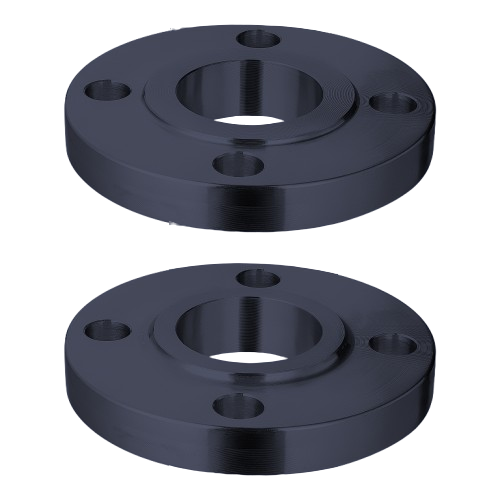

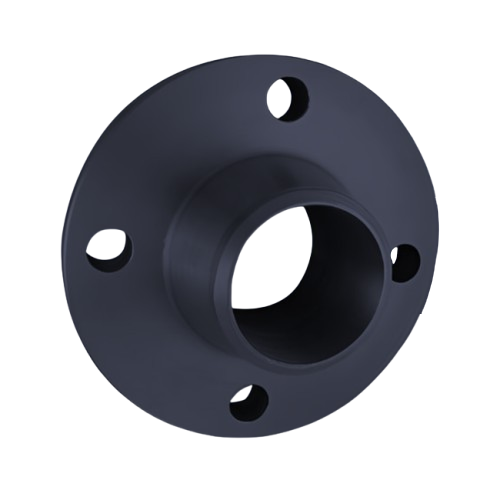

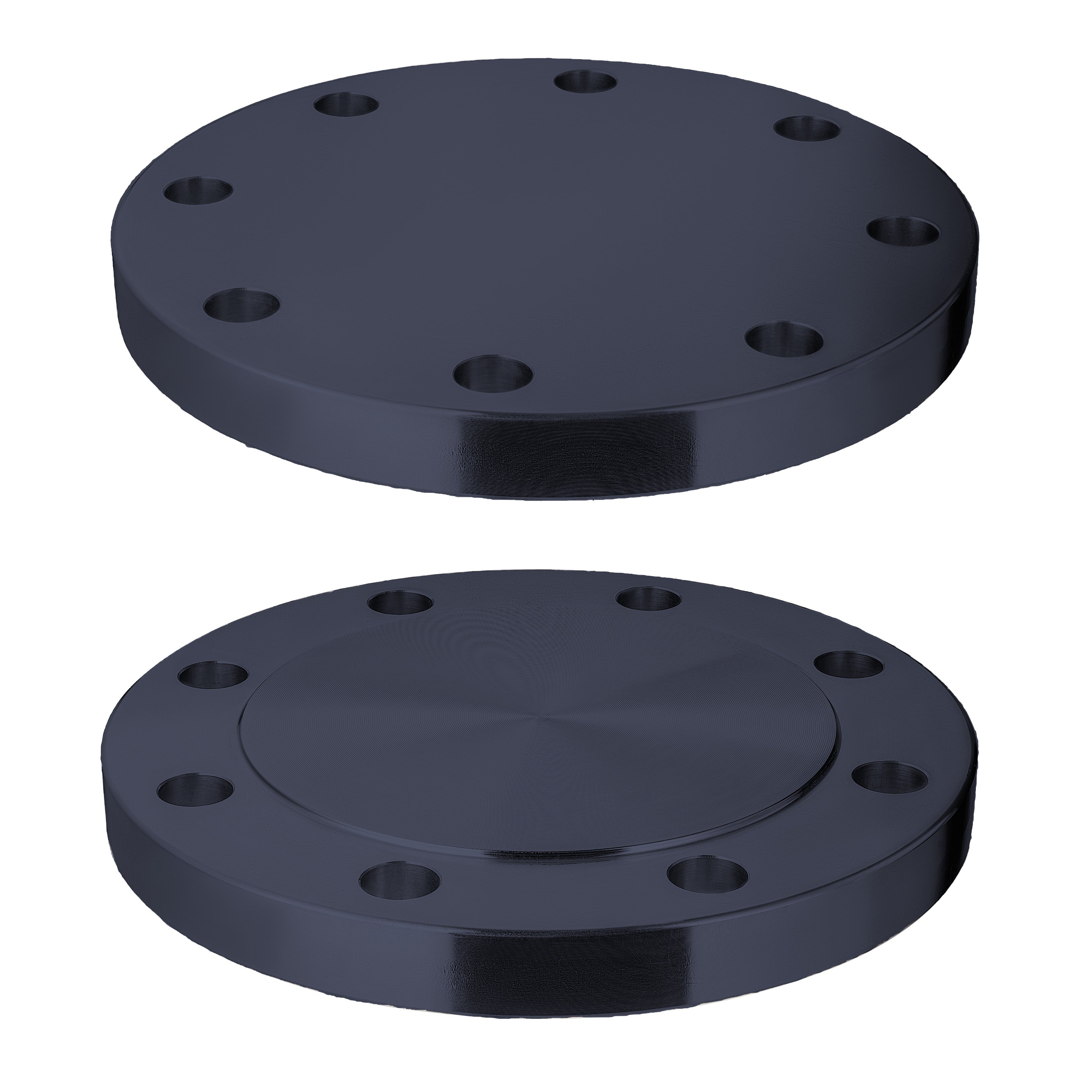

1. Superior Strength and Durability: Forged steel flanges are manufactured through a high-pressure forging process, resulting in a denser and more robust material. This makes them ideal for high-stress applications.

2. Corrosion Resistance: These flanges are often treated to resist corrosion, making them suitable for harsh environments such as offshore oil platforms and chemical processing plants.

3. High Pressure and Temperature Tolerance: Forged steel flanges can withstand extreme conditions, ensuring reliable performance in power generation and heavy industrial applications.

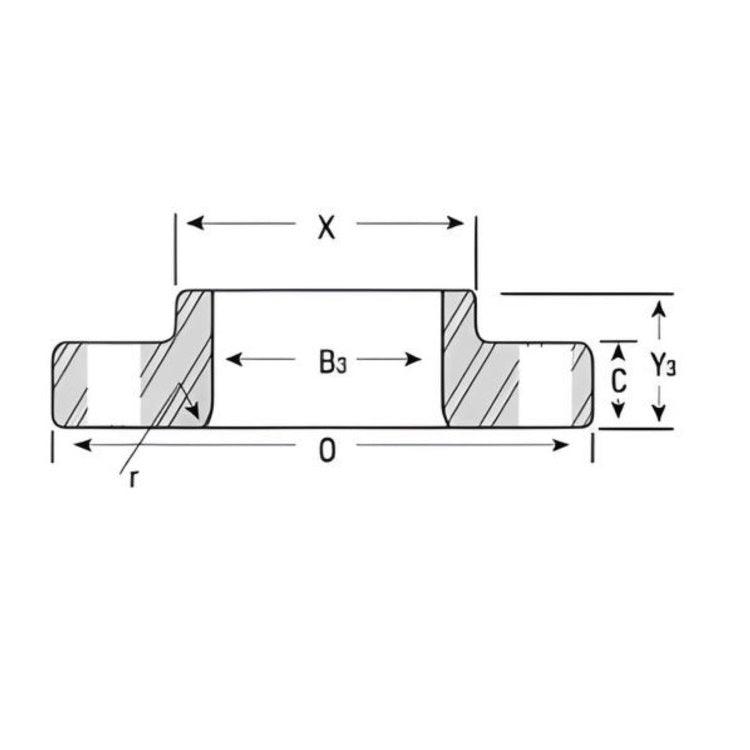

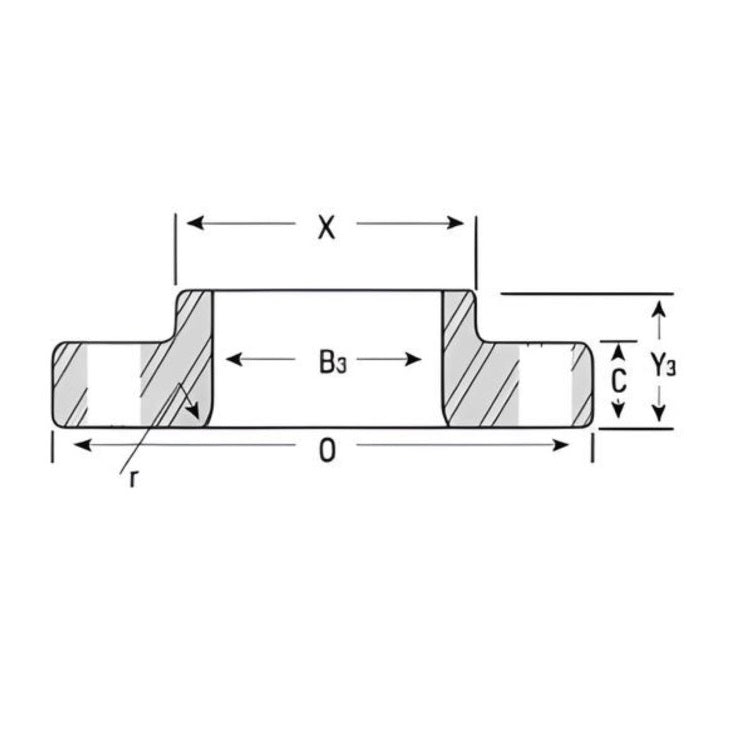

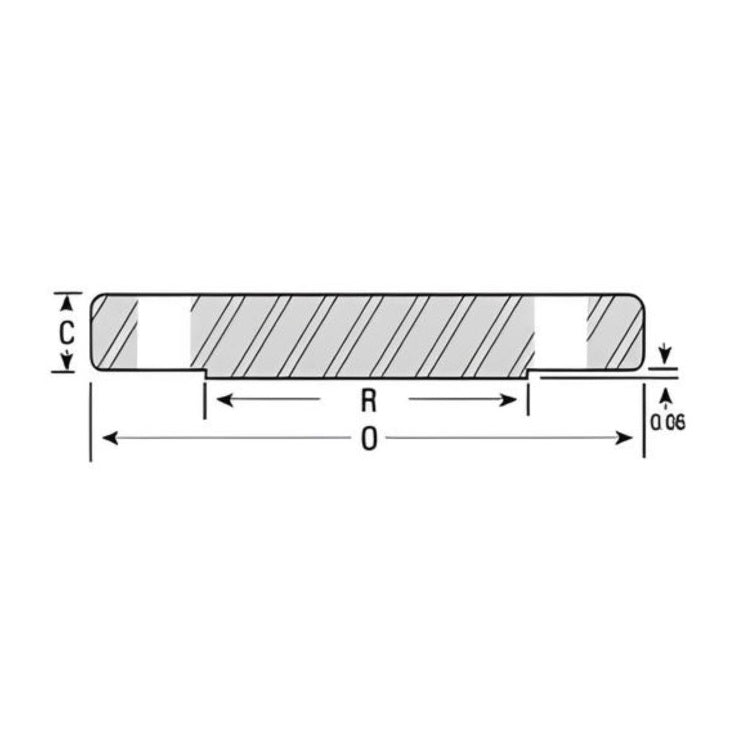

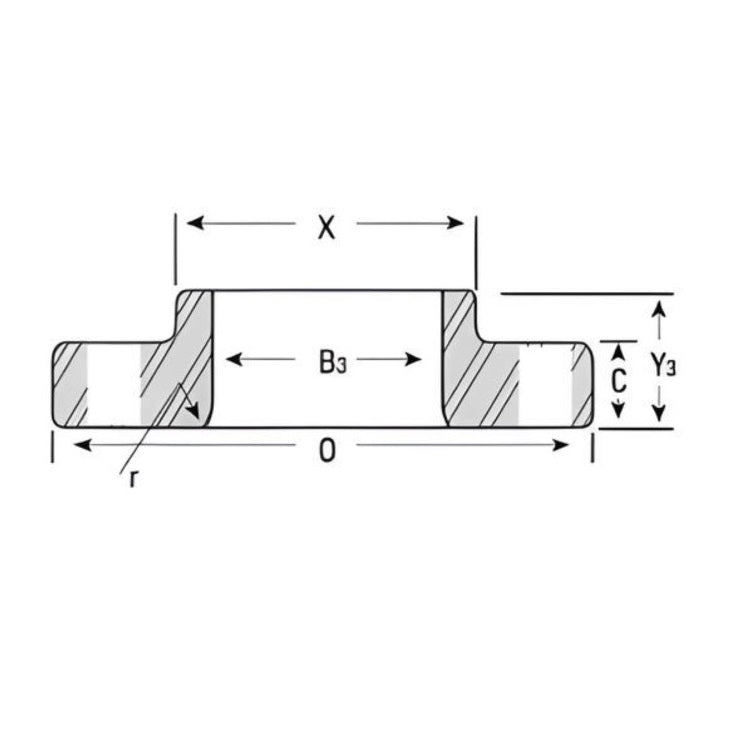

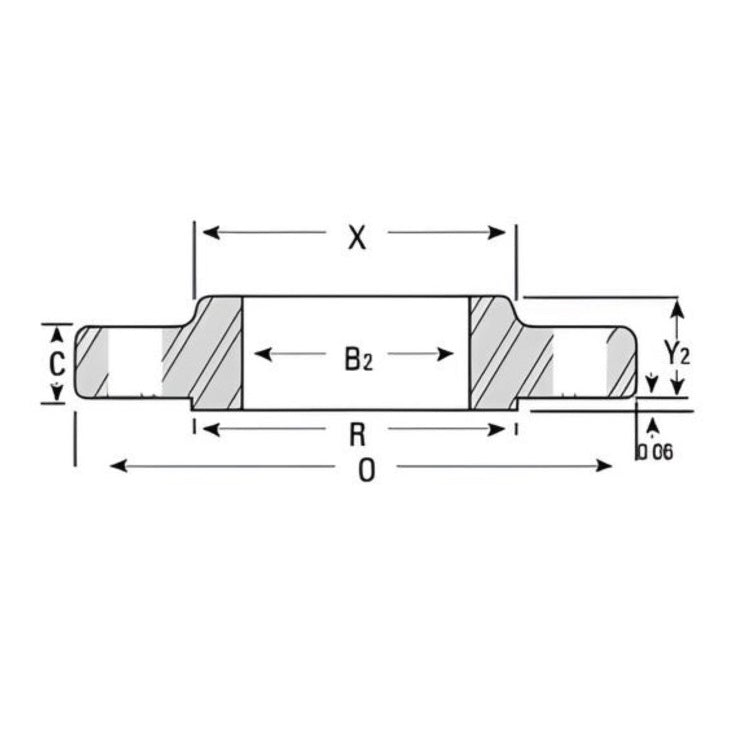

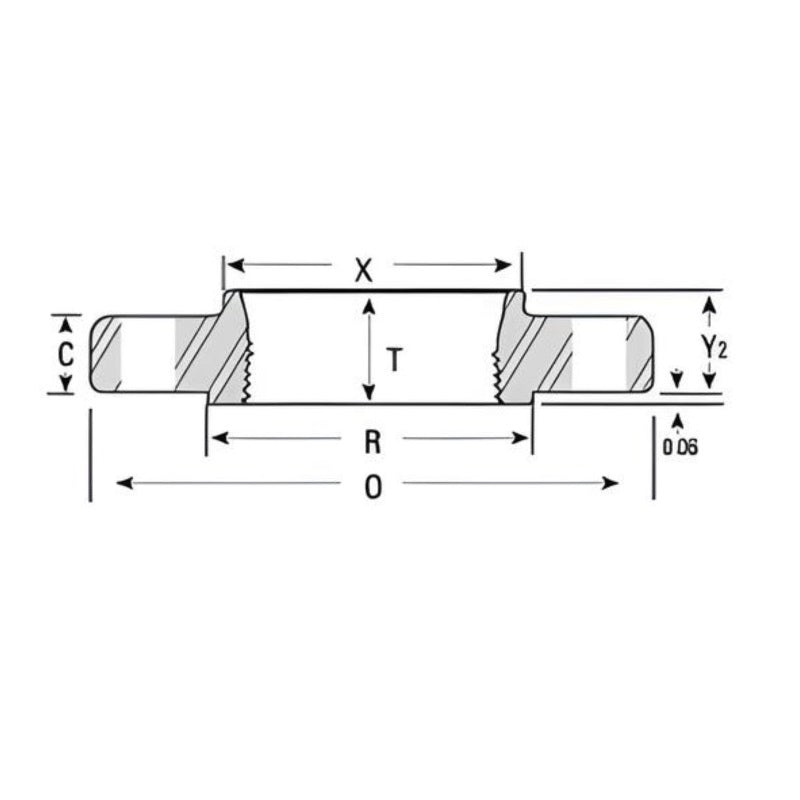

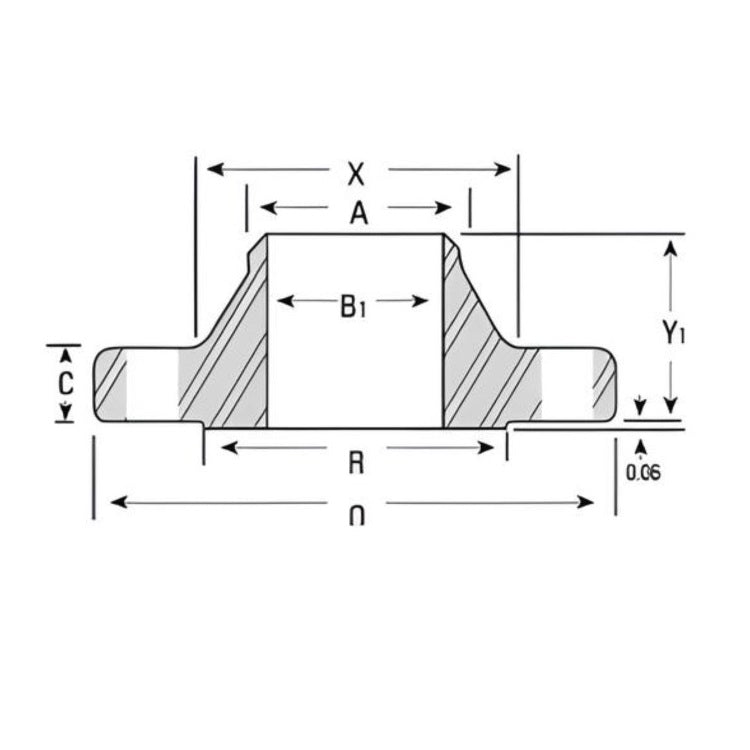

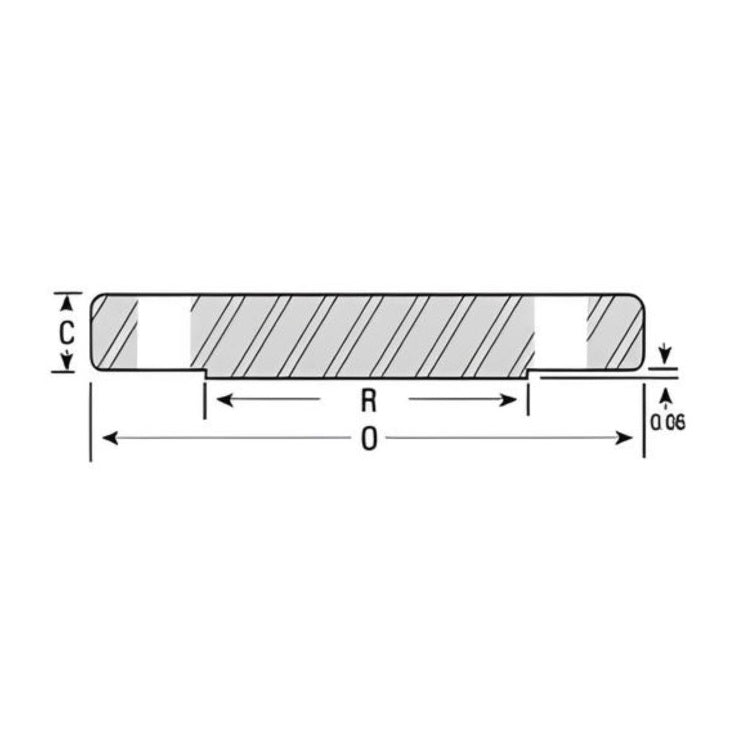

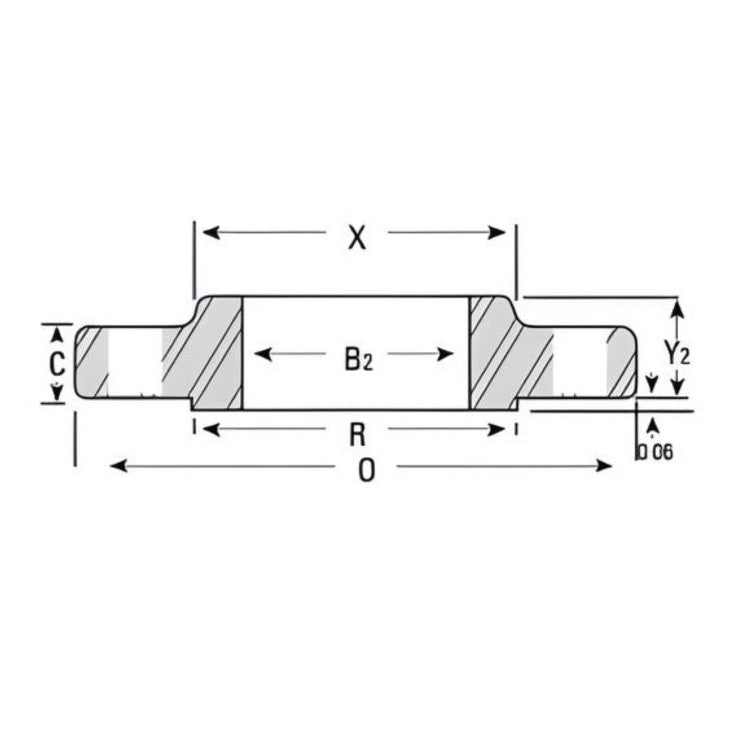

4. Customizable: Available in various sizes, shapes, and specifications, forged steel flanges can be tailored to meet specific project requirements.

Applications of Forged Steel Pipe Flanges

• Oil and Gas Industry: Used in pipelines to transport volatile substances at high pressures, ensuring secure connections and preventing leaks.

• Power Generation: Essential in systems that operate under high thermal and mechanical stresses.

• Petrochemical Industry: Provide reliable connections in environments exposed to corrosive substances.

• Construction: Used in various structural applications requiring durable and strong connections.

Manufacturing Standards

Forged steel pipe flanges are manufactured according to various standards to ensure quality and performance:

• ASME B16.5: Standard for pipe flanges and flanged fittings.

• ASME B16.47: Standard for large diameter steel flanges.

• MSS-SP44: Standard for steel pipeline flanges.

Conclusion

Forged steel pipe flanges are indispensable in many industries due to their strength, durability, and versatility. Whether in the oil and gas sector, power generation, or construction, these flanges provide reliable and long-lasting connections that meet the demands of high-pressure and high-temperature environments.